Company:

Sunshade

Project Details

Fabric 1

Z16 in Charcoal from Rainbow Shade NZ

Producer/Manufacturer:

OTHER

Primary Use:

Main Fabric

Design Name

Leah Huang, Z

Design Company

Zones Landscaping Hamilton

Subcontractor Name

Excavator – Curtis, Confined Contracting. Vulcan steele pipes. Waikato ready mix concrete. Onsite engineering brackets to posts.

Project Manager Name

Leah Huang

Project Manager Company

Zones Landscaping Hamilton

Please describe the project specifications

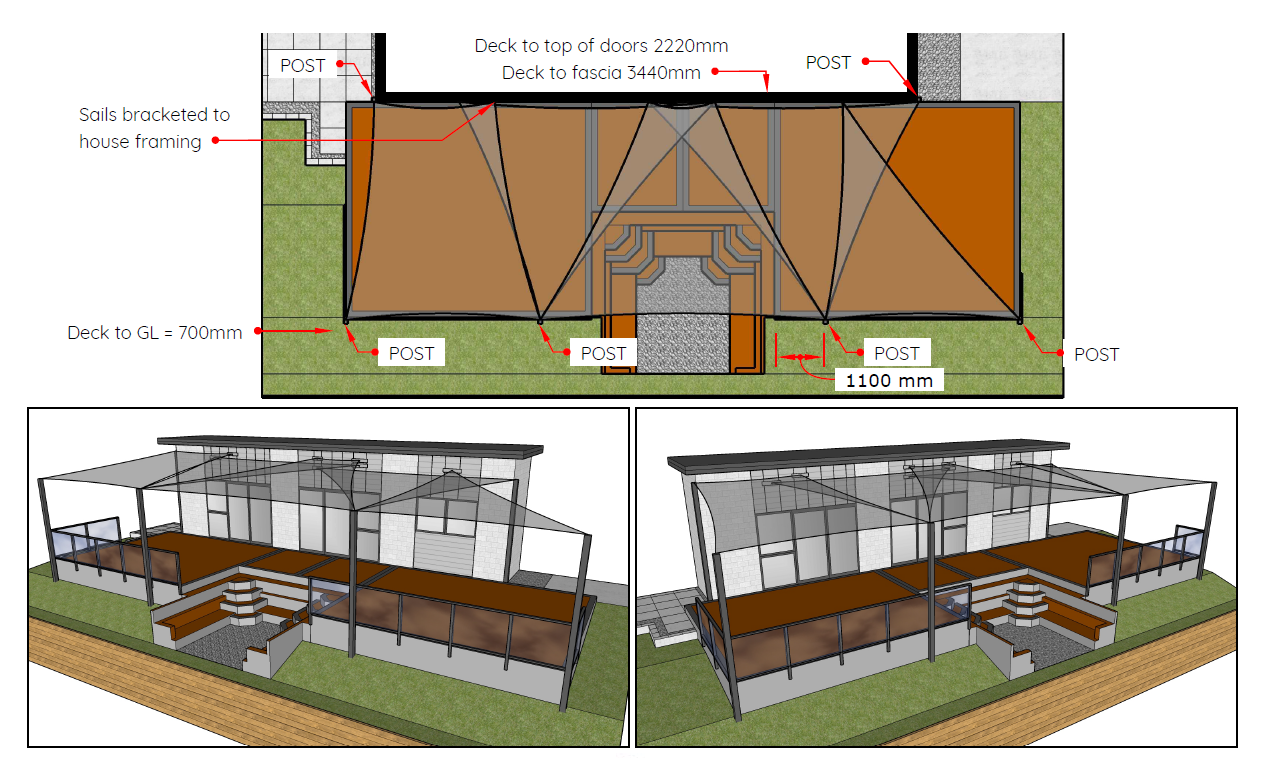

A cool looking concept drawing was provided, consisting of three straight-line triangle shades plus two rectangles, all less than 3° angles on virtually the same plane.

The design concept suggested the internal sail fixings should be fixed directly to the house, as close as possible, with four poles on the external side just off the deck, and two beside the house on the deck.

It needed to provide shade for the north-facing deck and the house interior, in an extreme high wind zone.

The job needed to be aesthetically pleasing for the end-customer and in keeping with their modern lifestyle property aesthetic, and enable the customer to retain unhindered views of the landscape from the deck.

Our client was a landscaper who had designed and sold a client on an architectural shade sail concept, which was designed without expertise in shade sail detailing, engineering, and installation.

We were tasked with carrying out the shade sail project and making it work within the specs - three straight-line triangle shades and two rectangles, all at virtually the same height.

The designs required the internal sail fixings to be fixed directly to the house, as close as possible, with four poles for fixing on the external side just off the deck, and two beside the house on the deck.

What is unique or complex about the project?

CONCEPT

• A design issue was the sails were drawn as straight edges, without allowing for a catenary curve, and no gaps were allowed for between sails. We had to redesign and communicate this back to the end-customer through the landscaper.

• We were concerned about the lack of shade to be cast so adapted the design to allow for a steeper fall at the deck edge.

• The drawing didn't have the minimum 3° post angle, and the two posts on the house corner needed redesigning otherwise we would've broken the symmetry and ended up rubbing. So, we customised an outrigger bracket enabling a cleaner visual line and allowing for practical fixing.

• Working to the plans' measurements was challenging to ensure accuracy of fixing positions. The plans weren't too far off – just 100mm difference-ish to ensure stud fixing. Also tricky to ensure the four external posts were symmetrical to the measurements, and vice-versa with the building fixing points.

• Getting the sequence right for installing each sail was tricky, especially as they were very close together.

• Being on the same plane we couldn’t hyper them, so likely to catch more wind. It was challenging to adapt it to avoid any potential rubbing/wear.

COMMUNICATION

• We experienced communication challenges in the relay between us, the landscaper, and the end-customer, with added complexity of a language barrier with the landscaper (plus being the first job we’d done together). Our biggest issue was the landscaper not effectively passing on to the customer how our changes were going to affect the result.

CONTRACTORS

• Getting the digger in for the poles was hairy as we were augering in from the paddock over a retaining wall 1.4–1.5m high - touch-and-go! The operator found some dirt for a ramp and got the height needed to elevate the auger without hitting the wall. Glad to have the operator to help solve the challenge!

• The concrete truck stuck in the lower paddock, because the driver decided he wanted to shoot from the bottom up, despite our concerns. Anxious moments were had while waiting for him to get unstuck while concrete was hardening! Lucky it's funny to look back on now!

This job had plenty of challenges, but the main test was in simplifying a slightly unrealistic plan to make it workable in reality and articulating the changes with the end-customer.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG