Company:

Fresco Shades

Project Details

Fabric 1

Ferrari 502

Producer/Manufacturer:

OTHER

Primary Use:

Main Fabric

Design Company

`Fresco Shades

Fabrication Company

Fresco Shades

Installation Company

Fresco Shades

Please describe the project specifications

We were approached by this kindergarten as they were running out of space and needed to create a sheltered all-weather area for their kids on their L shaped deck. Shade sails were in place, but these were old and no longer fit for purpose, given the pre-school wanted to be able to use the space all year round, especially in summer, but also on rainy days.

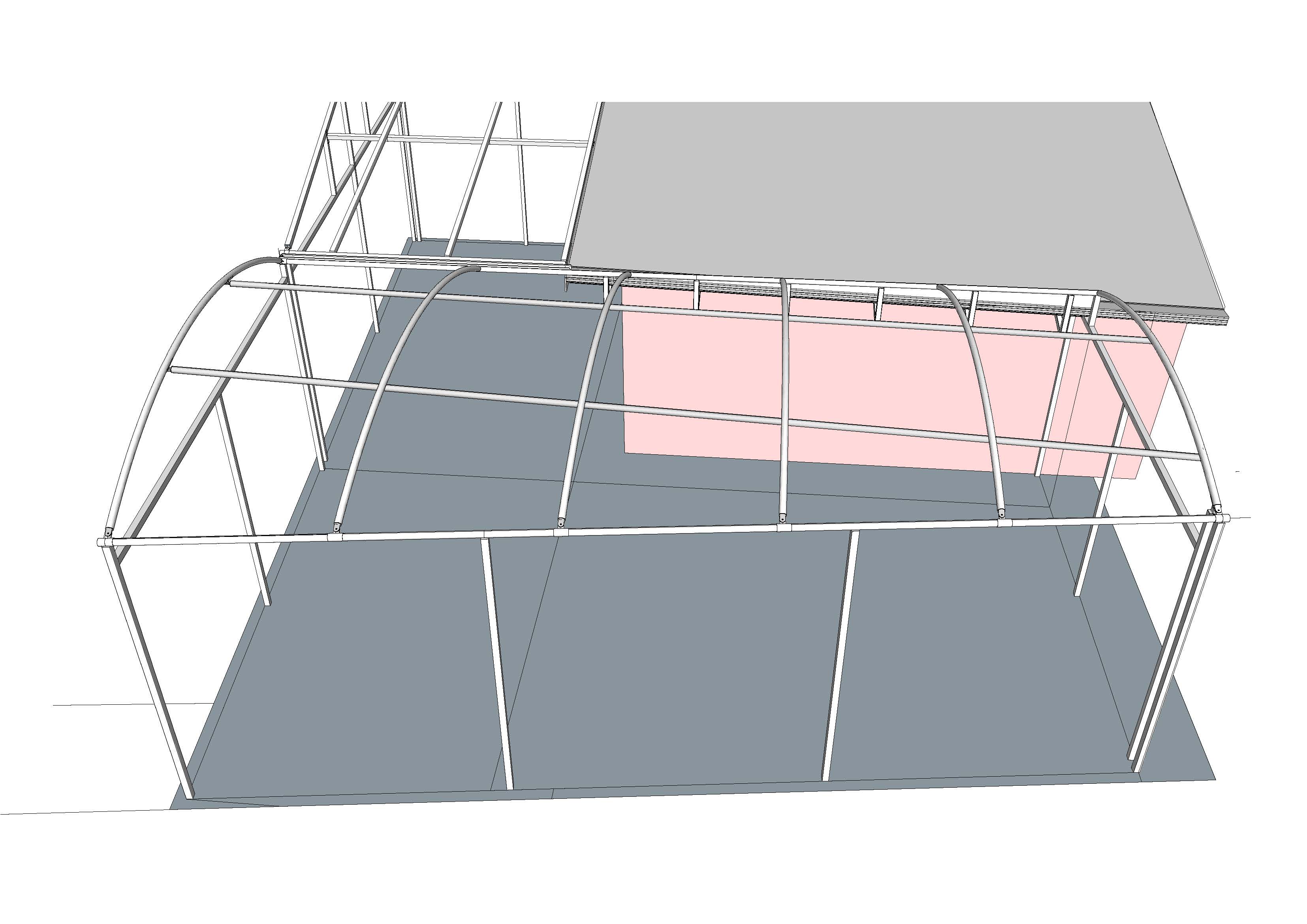

We designed two conjoined canopies, one a standard curve, the other a reverse lean to, with framing for the subsequent curtains to be fitted to.

What is unique or complex about the project?

Someone had fun designing this building! Aesthetically it was an interesting shape, comprised of multiple angles – the building and even the decks, on both sides. There was only one area on each side that was a true square, the rest was angled and of varying heights and roof styles. We have come across some complicated designs before, but none quite this quirky. To say it was a challenge to design for this project was an understatement.

Timing was another issue – the project was signed off November, our busiest time of the year, and the client wanted the installation completed in January, during first week back after the holidays. Just as well the installers were coming off a break, as they needed all their skills and thinking outside the square to make this project work.

This was a highly technical job that challenged our design team, the level of detail required was considerable. Considering all the varying angles and heights, everything had to be absolutely accurate to make these canopies work. We were joining a standard arch to a sloping reverse lean to.

Joining the 2 areas was a challenge due to the steep angle of the gable end, and the height difference between the two. Add to this both the gutters and the soffit on the building also sloped – we couldn’t follow that slope without creating further complications, so we leveled the back rail – however this meant each bracket had to be made individually at different heights and had to be mounted in a specific spot to fit properly.

The final part of the puzzle was framing for the curtains, this required square posts to be facing each other, and with angles present everywhere, a multitude of double-posts, flashings and static panels had to be installed in order to make this Canopy work with the sides.

We decided not to make the roof to start with, but to assemble the framing on site first to make sure everything fitted. Our designer helped install so that he could explain the details of exactly how the frames would attach, and in what order and to make sure it all fitted correctly. Thanks to total attention to detail, the frame fitted perfectly, and we were able to press go on the canopy roofs.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG