Company:

Ehmke Manufacturing Company, Inc.

Project Details

Fabric 1

1000 Denier Nylon - MIL SPEC

Producer/Manufacturer:

MMI Textiles

Primary Use:

Main Fabric

Fabric 2

2.2# Polyethylene Foam, Hydrophobic

Producer/Manufacturer:

F.P. Woll Inc.

Primary Use:

Foam Insert

Fabric 3

Webbing & Fastener Tape

Producer/Manufacturer:

MMI Textiles

Primary Use:

Webbing/Narrow Fabric

Engineer Name 1

Kayla Bleier

Engineer Company 1

University of Pennsylvania Rocketry Team

Design Name

Chris Jachimowski

Design Company

Ehmke Manufacturing Company, Inc.

Fabrication Name

Bob Rosania

Fabrication Company

Ehmke Manufacturing Company, Inc.

Project Manager Name

Laura Ogden

Project Manager Company

Ehmke Manufacturing Company, Inc.

Installation Name

Kayla Bleier

Installation Company

University of Pennsylvania Rocketry Team

Please describe the project specifications

Project Description:

When an Ivy League university’s rocketry team set its sights on the 18th Annual International Rocket Engineering Competition (IREC) in Midland, TX, they turned to our industrial textile end-product company for a mission-critical partnership. The IREC brings together over 2,000 university students, faculty, mentors, and aerospace professionals from around the world to test advanced rocketry concepts—launching rockets to altitudes of 10,000, 30,000, and 45,000 feet using solid, liquid, and hybrid propulsion systems. This is not your Middle School rocket hobbyist endeavor—it’s the proving ground for tomorrow’s aerospace engineers.

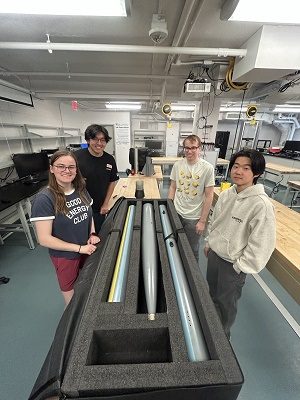

Through our Prototype Partnership Program (PPP), a 14-member student engineering team collaborated directly with our technical experts to design and fabricate two core components:

1. Custom rocket grid fins—critical for stabilizing and guiding the rocket in flight.

2. A comprehensive ground support transport system—an innovative, soft-sided carrying case solution with internal engineered foam support to safely

transport the rocket and all its systems to the remote launch site.

This transport system supported not only the rocket's propulsion and structural components but also the student team's proprietary telemetry and payload systems—ensuring every piece arrived in perfect condition.

Project Complexity:

The engineering challenges in this project were significant:

• Precision Fabrication: Rocket grid fins were laser-cut from a proprietary material to extremely tight tolerances. Surface finishing (sanding and polishing) was

performed to ensure optimal aerodynamic performance.

• Custom Transport System Design:

o Human-portable for field deployment with rapid access to components.

o Engineered foam interiors that strategically cradled delicate electronics, propulsion elements, and payload, supporting their center of gravity during transit.

o Durability: Built from hydrophobic, puncture-resistant materials to withstand the harsh handling and environmental conditions of desert launches.

o Reusable Efficiency: Designed for annual deployment, the modular cases allow for quick setup and teardown—minimizing pre-launch stress and

maximizing usability.

Project Results:

The true results of the Project demonstrated the cohesive collaboration between industry & academia delivering measurable success. The rocket and its support system were completed on time and under budget. More importantly, the student team gained hands-on experience in “real-world engineering practices”—project management, rapid prototyping, testing, and quality control—aligned with aerospace industry standards.

The result? A successful 8,000-foot launch, with the team finishing 82nd out of 216 international teams in launch accuracy—an outstanding achievement in their second competition. Our company’s contribution went beyond fabrication; we empowered the next generation of aerospace engineers by transforming theoretical classroom knowledge into flight-ready innovation.

Supporting the Future of Aerospace

This project stands as a testament to the impact that industry-academic partnerships can have. Through a shared commitment to excellence, we helped bridge the gap between education and application—delivering real-world solutions that reached new heights.

Relevant Information: Learn more about the competition at www.soundingrocket.org – IREC 2025

Content is submitted by the participant. ATA is not responsible for the content descriptions of the IAA award winners.

Ehmke Manufacturing Company

Ehmke Manufacturing Company

University of Pennsylvania Rocketry Team

University of Pennsylvania Rocketry Team

TEXTILES.ORG

TEXTILES.ORG