Company:

Fabritecture (UFS Australasia Pty Ltd T/A Fabritecture) Gold Coast, QLD

Project Details

Fabric 1

PVC Mesh

Producer:

Serge Ferrari North America Inc.

Supplier:

Innova International

Engineer Company 1

Greenup Design International

Design Company

Fabritecture

Architect Company

JCY Architects

Fabrication Company

TFS Textile Fabrication Services

Subcontractor Company

Fabritecture

Project Manager Company

Fabritecture

Installation Company

Fabritecture

Please describe the project specifications

As part of the initiative to replace the existing Princess Margaret Hospital, the Perth Children’s Hospital redevelopment included a complete upgrade of the Hospital and its facilities.

Shade structures were required for an outdoor children’s playground located at the new Hospital.

Once open, the new Perth Children’s Hospital will host internationally and locally recognised organisations for paediatrician, clinical research, and tertiary learning.

What was the purpose of this project? What did the client request?

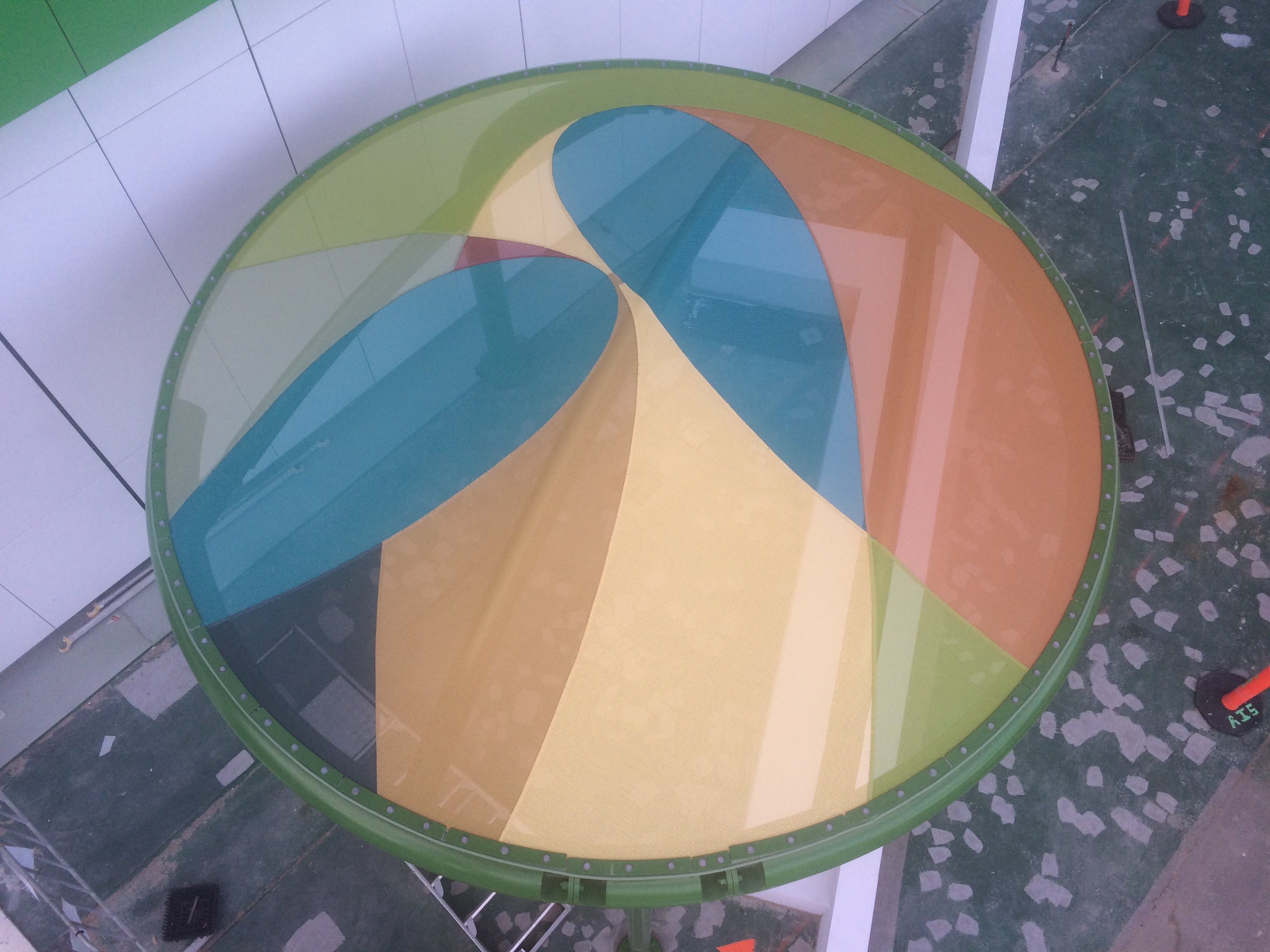

The client requested an architecturally creative, yet functional shade solution for the children’s playground that would compliment the surrounding environment and completed infrastructure. The final shape of the design combined complex curved steel geometry with tight radius’ and creative fabric patterning.

The interactive nature of the playground required the structures to be engaging and fun, yet functional and structurally sound. The canopies are fun and colourful to match the Hospital’s architectural colour scheme, but intricate in detail.

What is unique or complex about the project?

Extra consideration required to get the steel to work with the radius of the curves as the nominated steel was larger than usual. The pipe sizes of the steel created a level of complexity to the curvature within the geometry of steelwork.

Particular locations of connection details needed consideration based on overall size to generate efficient shipping and erection of the structure

Completely custom fabric patterning was created to match the specified colour scheme of the architect. To guarantee fabric patterns lined up correctly, a detailed patterning and stitching process was required. This process ensured correct alignment of the wefts and weaves for each piece.

Smaller patterns needed to align properly to ensure the fabric nested into the roll widths correctly, which minimised wastage and maximised usage.

The entire site was at a height with limited accessibility, meaning steel had to be crane-lifted to level 2 from ground and street levels. The shade structures had to be installed around the complicated existing landscape of the playground, which required additional planning and coordination of installation machinery.

Attention to detail and extra protection were required during deliver and installation due to the high-gloss paintwork coating the steel. Packaging and bracing of the steel into containers was considered at lengths prior to shipment and delivery in order to avoid damage and protect the high gloss paintwork.

What were the results of the project?

The final shade structures met the brief, and the client was extremely satisfied. The end result created eye-catching shade canopies with a mixture of colourful fabrics and complex steel geometry.

The structures are an exciting and engaging addition to the Hospital’s redevelopment, providing a kid-friendly and interactive shade solution to the playground. This project emphasises the commitment of the Hospital and its facilities to the kids that use them.

It was fundamental that the shade canopies were functional, but also aesthetically pleasing and interactive for the kids in the playground.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG