Company:

ACE Geosynthetics Inc. Taichung City,

Project Details

Fabric 1

ACEGrid®

Producer:

ACE Geosynthetics Inc.

Supplier:

ACE Geosynthetics Inc.

Fabric 2

OTHER

Producer:

ACE Geosynthetics Inc.

Supplier:

ACE Geosynthetics Inc.

Fabric 3

OTHER

Producer:

OTHER

Supplier:

ACE Geosynthetics Inc.

Please describe the project specifications

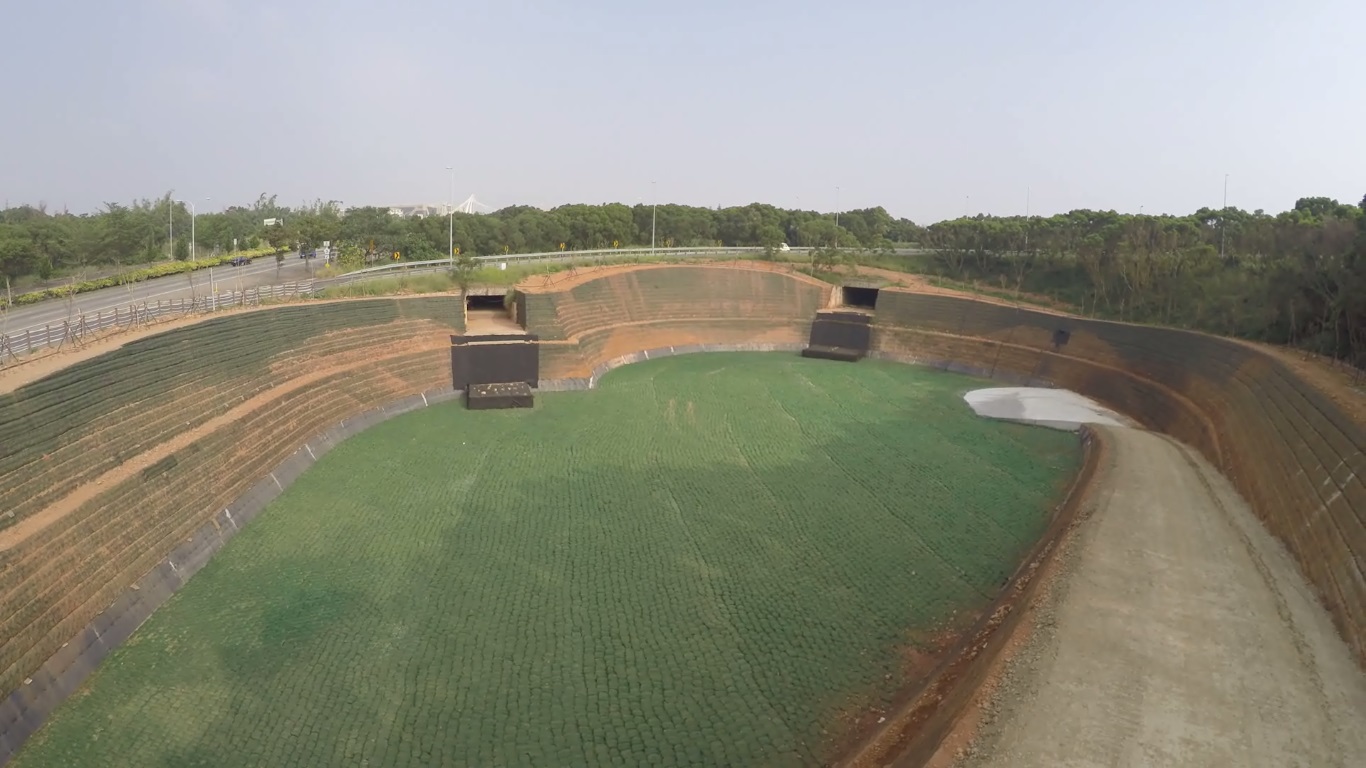

This is a large geosynthetic detention basin project which is located at Northbound Ramp of Shalu Interchange, Central Taiwan. The total area of the site is around 6,000 m2. The expected storage volume of storm runoff is 20,644 m3.

The whole project includes several steps. First of all, it starts with tearing down the original reinforced concrete drainage canal because of its insufficient capacity. Next, the entire job site is excavated 10 m deeper. Thirdly, a reinforced structure with PET geogrids ACEGrid® and UV resistant high tensile strength woven geotextile bags ACEBag™ is built along the perimeter of around 300 m; the former provides the structure with fundamental bearing capacity while the latter confines the in-situ soils and prevents erosion. Lastly, it is the basin bottom, which measures about 3,500 m2. It is covered with geosynthetic clay liners ACELiner™ GCL and on top of them are soil-filled woven geotextile bags ACEBag™ that keep the liners fixed to the ground and allow vegetation to grow with a view to creating pond ecology. Besides that, the detention basin is connected to a rainwater harvesting and irrigation system which collects, recycles, and makes good use of the rainwater. It, therefore, proves to be multifunctional and much more beneficial not only because of its capability of flood control but also its emphasis on environmental sustainability.

What was the purpose of this project? What did the client request?

Over the last decades extreme climate change has increased the frequency of unusual heavy rainstorms which usually bring tremendous amount of precipitation. Unfortunately, the streams in the area were not ideally controlled and the original surface drainage system failed to effectively deal with the runoff. Furthermore, the steep terrain around this place makes the runoff gather faster and shortens the time for water accumulation. All these factors resulted in floods and other natural hazards when typhoons struck Taiwan or torrential rain poured. With a view to solving this problem once for all, the municipality decided to turn the unused space at the ramp nearby to a large detention basin with a proper drainage system which should have the perfect capacity to handle abrupt increase of runoff water and is optimal for disaster prevention. The project owner demanded green engineering be the core principle in all stages of the project in order to ensure environmental sustainability. To attain this end, geosynthetic materials were included. Woven geogrids are light, tenacious, and easy to use. Most importantly, they can be incorporated with in-situ soils to construct reinforced structures. It helps cut down on the concrete and the project’s carbon footprint, and embodies the very idea of green engineering.

What is unique or complex about the project?

The most challenging thing about this project is the water. To maintain the structure stable, geogrids are used. The friction between soils and geogrids increases the confining pressure which enlarges the soils’ apparent cohesion and prevents fine particle loss. Apart from that, the geobags in the front help avert surface erosion and deformation, and the proper drainage keeps the excessive moisture out of the structure.

The other feature about this project is the circular design. ACEGrid® GG series is flexible, which makes it easy to be adjusted to various landforms and on-site conditions during construction. Also, the job site is limited by the existing ramps so the land boundaries should be taken into account in the design. Therefore, it requires more attention and efforts to make sure the design and calculation are accurate so as to meet the need of having the expected storage volume within the boundaries.

This detention basin is built within 5 months. It proclaims geosynthetic solutions are more timesaving and more efficient in comparison to traditional construction method. The labor cost is thereby lowered and the undesirable impact on the surroundings during construction is minimized.

What were the results of the project?

The whole project was finished in November 2015 and in the next 6 months after its completion torrential rains have hit Taiwan ferociously more than 10 times, but, fortunately, no casualty happened thanks to the properly designed drainage system, which successfully caught all the surface runoff in this area and channeled it to the detention basin for temporary storage; only afterwards did the detained water gradually discharge to the downstream. The basin lessened the burden the rainwater imposed on the whole area and also reduced the likelihood of disastrous occurrences with evident effectiveness. Apart from the purpose of flood control, the geosynthetic solution even proves to be much more environmentally friendly by giving the plants and trees a suitable base to thrive and the animals a more inhabitable place to dwell. Making the best use of limited land resource in the city without doing any damage is remarkable; yet, making an artificial structure blend in with the surroundings is exemplary.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG