Company:

Geiger Engineers

Project Details

Fabric 1

SHEERFILL I

Producer/Manufacturer:

Saint-Gobain Performance Plastics Corp.

Primary Use:

Main Fabric

Fabric 2

SHEERFILL II

Producer/Manufacturer:

Saint-Gobain Performance Plastics Corp.

Primary Use:

Secondary Fabric

Engineer Name 1

David Campbell PE; Keith MacBain PhD, PE; Eric Dahl PE

Engineer Company 1

Geiger Engineers

Design Name

David Campbell PE; Keith MacBain PhD. PE; Eric Dahl PE

Design Company

Geiger Engineers

Fabrication Name

Thomas Wuersch

Fabrication Company

Pfeifer Structures

Subcontractor Name

John Wozniczka III PE

Subcontractor Company

JPW Structural Contracting Inc.

Project Manager Name

Gus Hernandez; Vinnie Mowers

Project Manager Company

The Hayner Hoyt Corporation

Installation Name

Thomas Wuersch

Installation Company

Pfeifer Structures

Please describe the project specifications

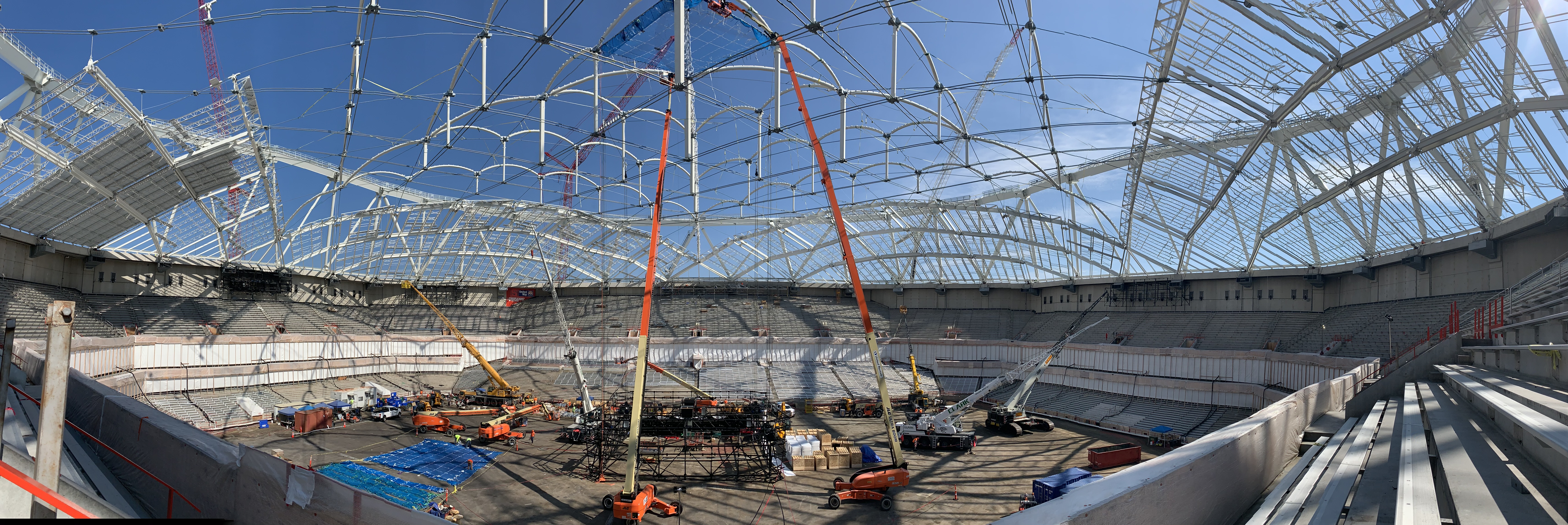

The JMA Wireless Dome (formerly the Carrier Dome) at Syracuse University, a 50,000 seat multipurpose domed stadium, opened in 1980. The Dome’s original air-supported roof, although economical to construct, had significant operating demands including the need to maintain constant positive interior pressure to support the roof and a limited ability to support snow. Any significant snow accumulation had to be melted or manually removed to prevent the roof from inverting. As the roof fabric was approaching the end of its design service life, the University chose to replace the roof with a new non-air-supported structure and tasked our firm with the design. In addition to the complexity of replacing an air-supported roof with a dissimilar structure, the University placed significant limits on the period of time the facility could be closed for construction. The Dome is heavily utilized by Syracuse Athletics for football, women's and men's basketball and lacrosse, requiring that the renovation allow for facility use from September through early March.

The Dome’s new roof is a first-of-its-kind cable truss and employs both tensioned fabric membrane and rigid panels to cover the stadium. It is an ingenious design that uniquely addresses the challenges of replacing the stadium’s original air-supported roof.

The new roof dramatically reduces the energy usage of the Dome as it no longer requires 24/7/365 continuous fan operation to keep the roof inflated, does not necessitate snow melt, and has significantly reduced the heat loss and gain of the old air-supported roof.

It is a testament to the construction team as well as the well-conceived design that the new roof was completed on time without the need to delay or postpone any scheduled Dome events. The finished structure efficiently overcomes complex challenges and now passively supports as much as 14,000,000 pounds of snow without the need for monitoring or intervention. It is a creative, innovative, and iconic addition to the University campus and the Syracuse skyline that will be utilized for many years to come.

What is unique or complex about the project?

The the new roof of the JMA Wireless Dome at Syracuse University Stadium is a unique project. The spans of the structure, the severe design snow loads, the need to minimize the impact on the existing stadium, and the constraints on construction made this a truly challenging endeavor for all involved. The primary structure was conceived to permit the heaviest construction to be executed from the exterior while the Dome remained in service and with rapid construction and cladding after the original roof was removed. The structure employs fabric cladding for its light weight, rapid installation, daylighting, and flexibility. Snow drifting studies were conducted to determine design loads for the roof, which resulted in peak design loads on the fabric region of 200 psf.

Compounding the construction challenges, the project was at a critical stage of construction in 2020 when the COVID pandemic struck with attendant complications and disruptions and yet was completed on time.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG