Company:

Tropical J's

Project Details

Fabric 1

Evolution 745

Producer/Manufacturer:

Sattler North America Corp.

Primary Use:

Main Fabric

Engineer Name 1

Ian Robertson

Engineer Company 1

Ian Robertson PHD

Design Name

Justin Barnes

Design Company

Tropical J's

Fabrication Company

Tropical J's

Please describe the project specifications

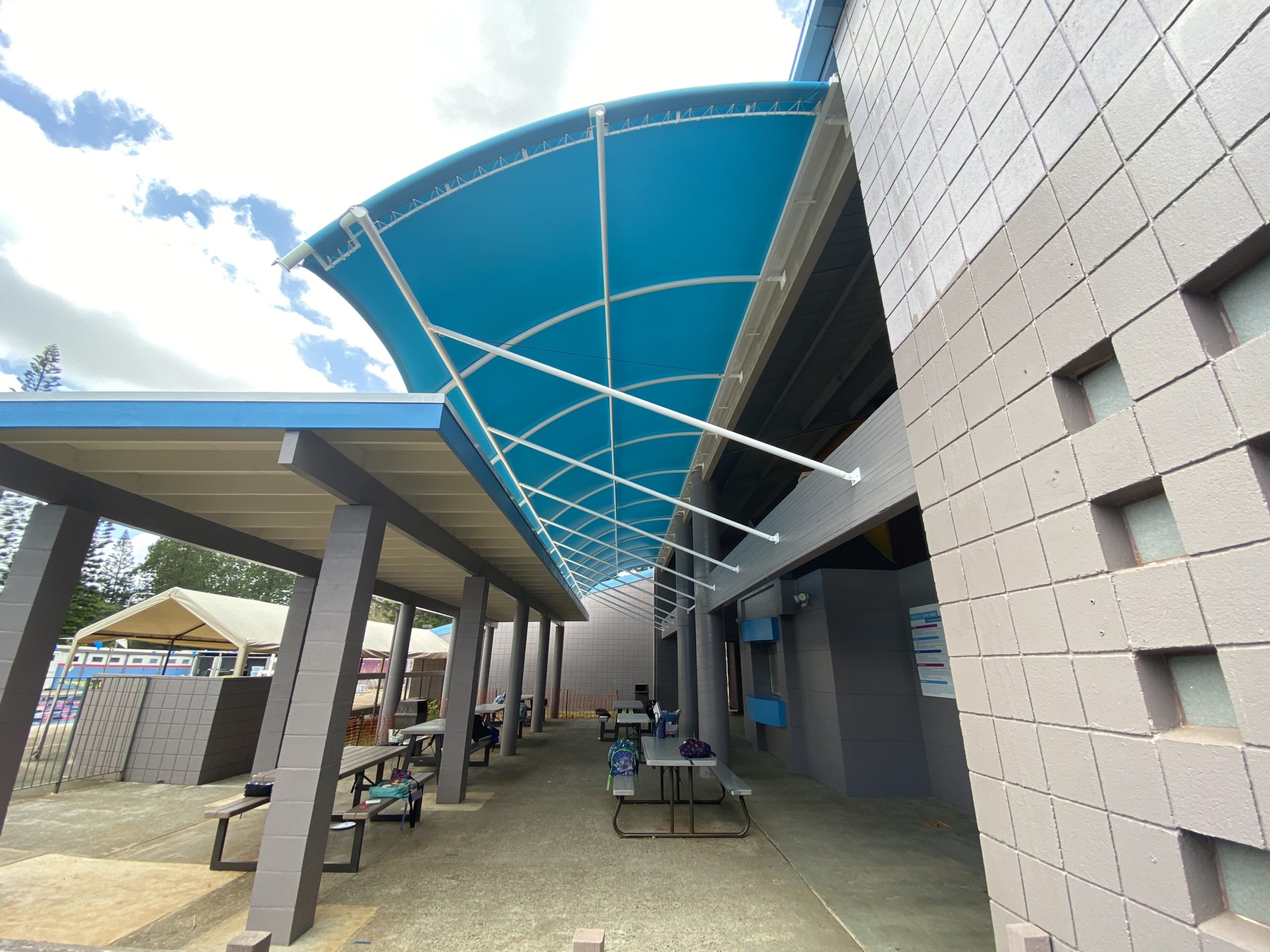

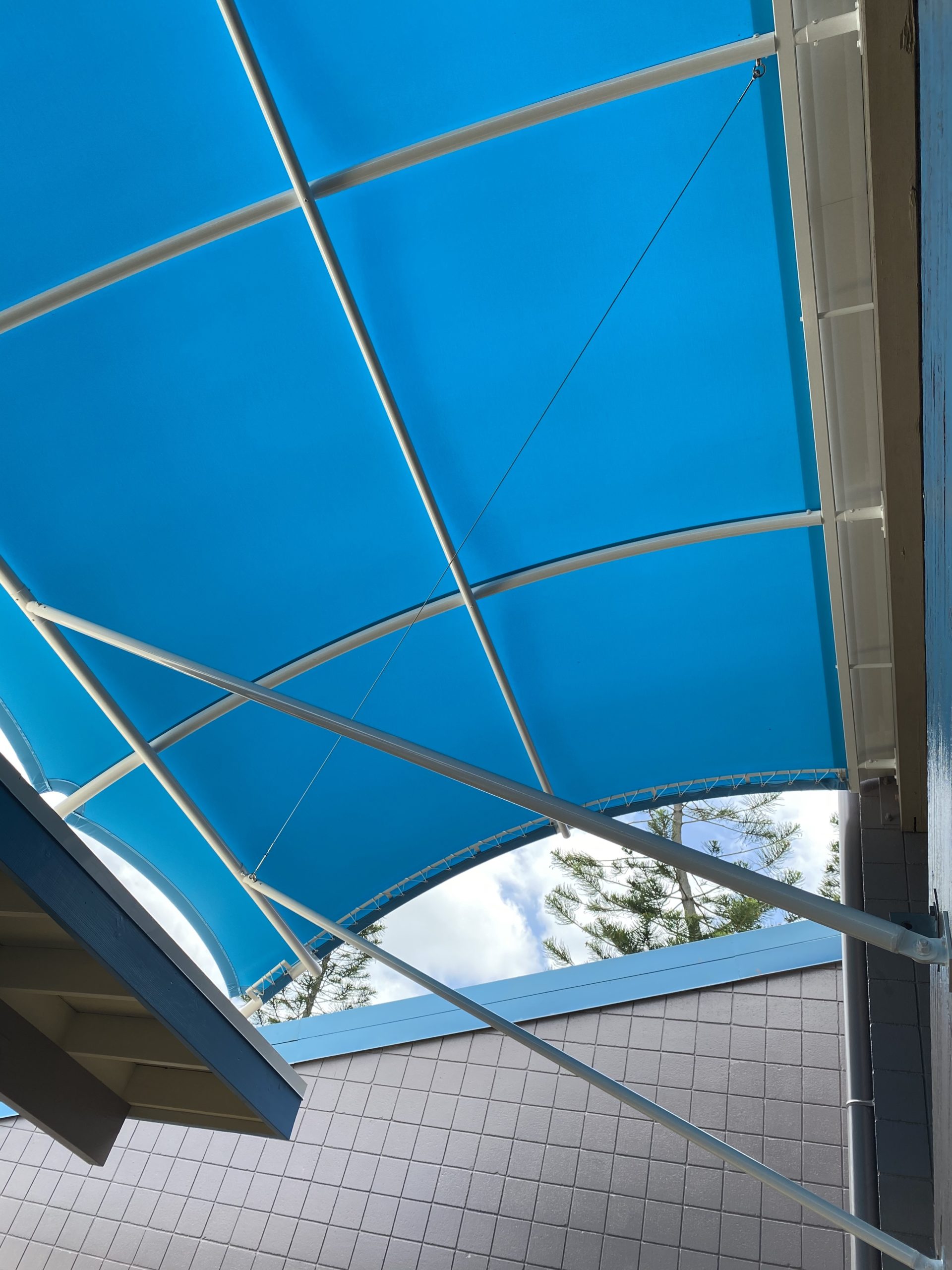

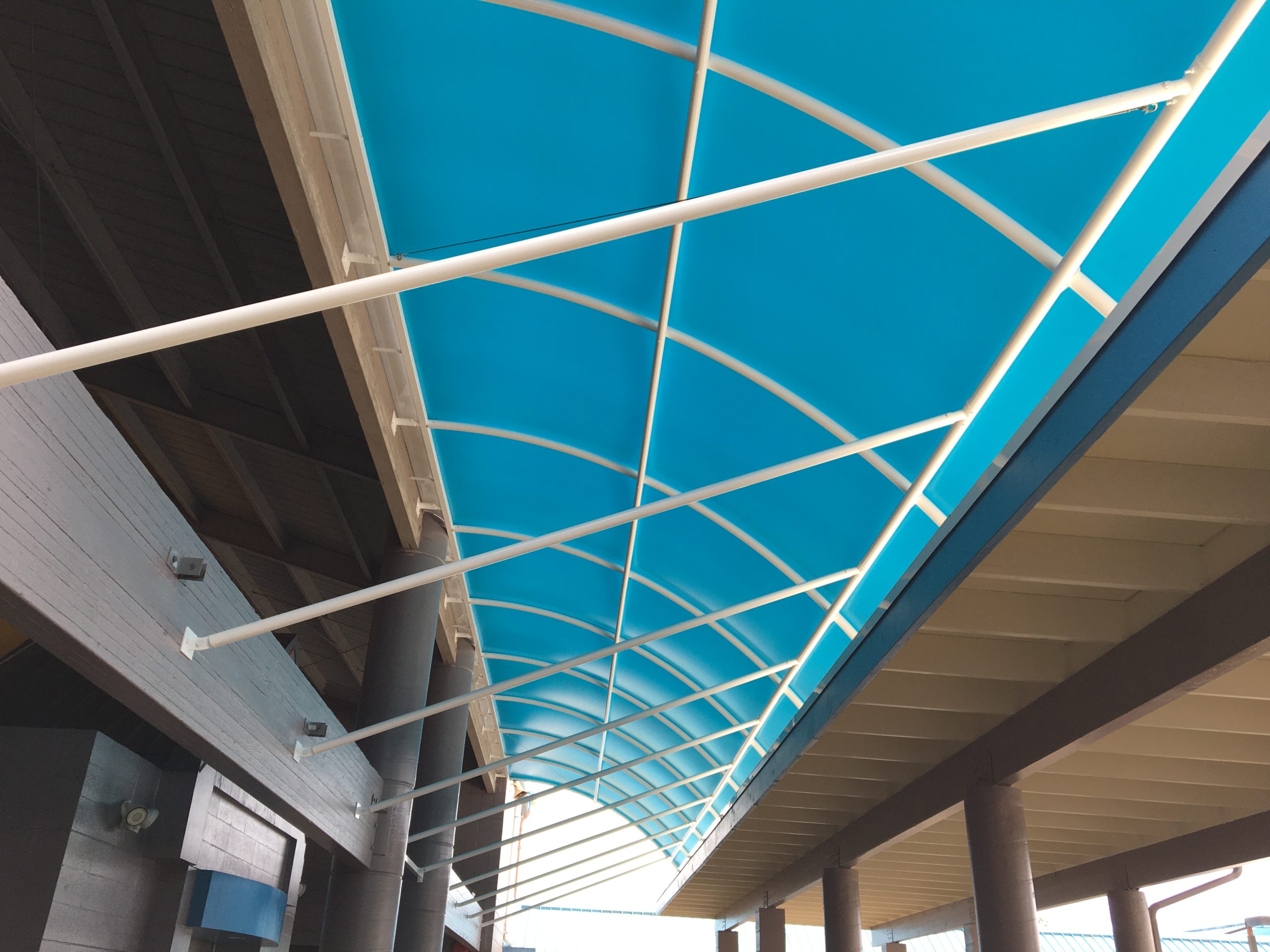

YMCA needed an awning to project out about 12' from a building and waterproof the space between the building and a new covered area. The size really called for a canopy, but the awning could not have posts or else it would trigger permit requirements which they were unable to obtain. We settled on a barrel shaped awning, and treated it as a "canopy" with posts acting as "comebacks". Due to the size we decided to use design elements of a cable tensioned canopy to execute the awning. The fabric is tensioned using stainless cables and threaded toggles.

What is unique or complex about the project?

The face of the building was wide open and the attachment points were either vertical concrete columns and horizontal wooden glue lams. Nothing on the face of the building was in the same plane. So we were unable to weld an awing up and bolt it to the building. Instead we came up with a head bar that had receivers on both sides. On the back side of the headbar, the receivers connected to small tubes with plates. This allowed us to account for the variation in depth behind the headbar. This gap was ultimately covered with a custom flashing. The front sleeves received the awning rafters and the entire thing was built up 22’ in the air.

We treated the “comebacks” as posts and used saddles to the front bar to allow the comebacks to each have their unique angles. The saddles were welded to pipes that went inside the main comeback pipes. This allowed for the custom lengths at each comeback. These pipes attached at the back wall via a tab/tab-plate allow for the custom angle for each comeback.

To top it all of this was an engineered product, so all of these attachments were approved by structural and allowed to be assembled in the field to account for all of the variations in the sit.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG