Company:

AGRU America

Project Details

Fabric 1

AGRUTEX 101 (AT101)

Producer/Manufacturer:

OTHER

Primary Use:

Main Fabric

Fabric 2

80 mil HDPE Double-Sided Microspike

Producer/Manufacturer:

OTHER

Primary Use:

OTHER

Fabric 3

200 mil AGRU Geonet

Producer/Manufacturer:

OTHER

Primary Use:

OTHER

Installation Name

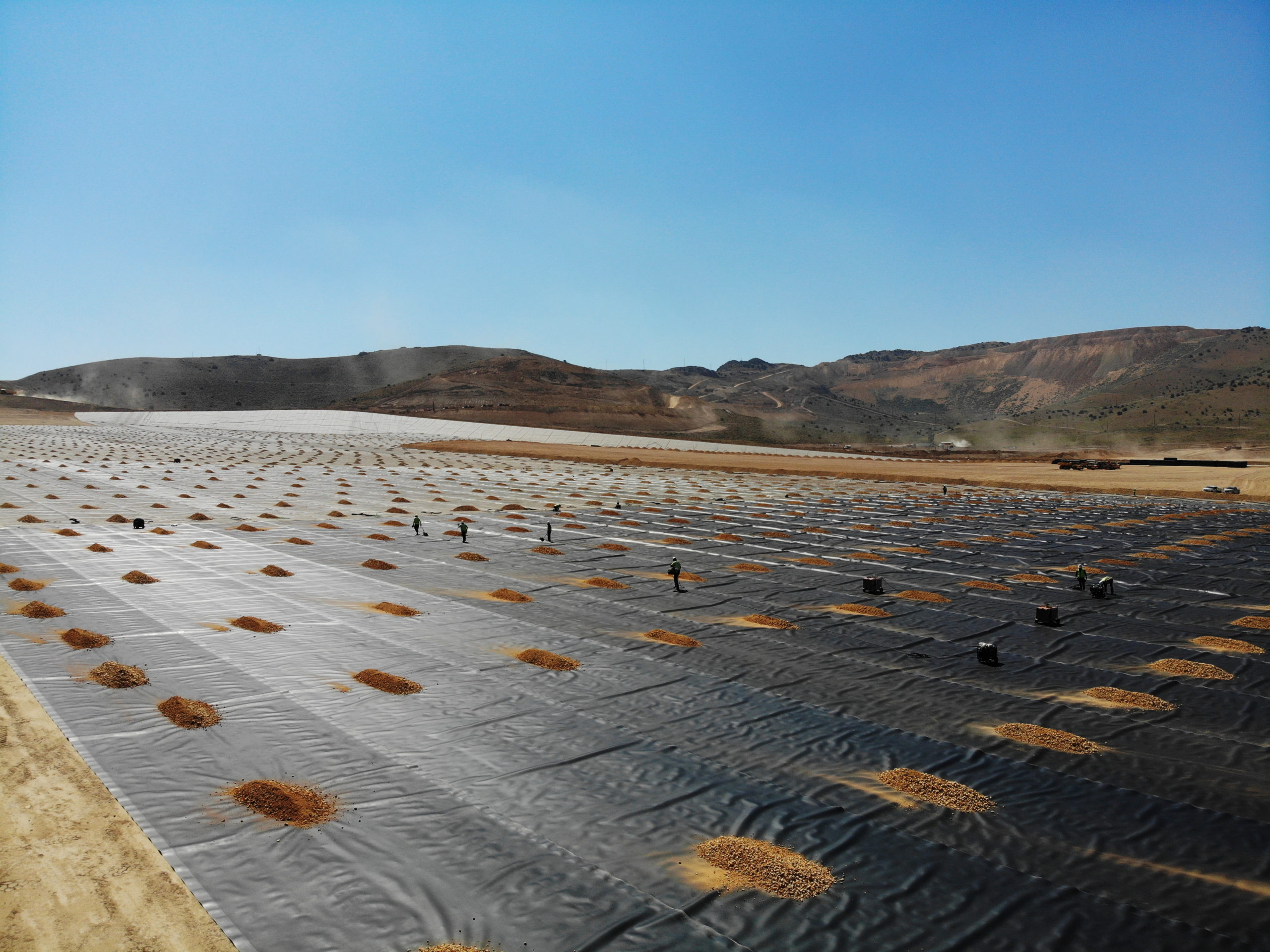

Heap Leach Pad

Installation Company

International Lining Technology

Please describe the project specifications

A northern Nevada mine and associated heap leach facilities began operations in 1986, utilizing a closed-circuit tertiary crushing system to mine and process gold and silver. In 2019, the system was upgraded to a single high-pressure grinding rolls (HPGR) crusher, which allowed mine owners to take full advantage of the region’s low average annual precipitation. With about 13 inches of rain a year, the mine could effectively operate 24/7. With the increased production capacity--and the existing heap leach pads approaching capacity--the mine owners requested the creation of a fifth, larger leach pad that would be able to support the mine for the next decade.

Modern mining operations rely on low-cost, high-efficiency technologies to keep the project profitable. Often, these mining operations utilize passive heap leaching to separate desired metals from crushed ores. AGRU's role was to manufacture and deliver millions of square feet of geosynthetic liner that would be necessary to build the containment system for the heap leach pad as well as the geotextile for its drainage system.

Video overview of the installation site: https://bit.ly/2UQ2OGE

What is unique or complex about the project?

AGRU America is in the business of manufacturing geosynthetic liners, geotextiles, and plastics for a multitude of industries, including large-scale mining. The mine's proximity to AGRU's Nevada facilities as well as its time-sensitive requirements made it an ideal project to pursue.

Designing and implementing an effective heap leach pad demands careful planning as well as a strong, long-term design. Planning is essential and done by reassessing the mine’s mineral resources as well as other factors. The client’s recent assessment determined that a fifth heap leach pad was not only required, but also essential for sustained year-around operations.

Two challenges set this project apart from others. First, the heap leach pad’s dimensions are massive. While most heap leach pads are on the order of hundreds of thousands of square feet, the pad that the client needed to last through the mine's end of life exceeded 10 million square feet. Under most circumstances, size does not matter. But the heap leach pad installation took place during the global pandemic, which caused numerous disruptions in the liner industry. Second, the heap leach pad had to be completed within a narrow timeframe to avoid production bottlenecks.

AGRU leveraged its decades of industry and manufacturing expertise to help assuage each challenge. To meet production requirements, AGRU leaned on its international presence to help ensure enough raw material would be available. To reduce installation time and keep the project on schedule, AGRU delivered the highest quality products on the market with many built-in time-saving features. AGRU’s liners, for example, feature smooth edge seams that can significantly help streamline installation speed. Additionally, AGRU regularly invests in R&D to find new ways to support its clients, such as CleanSeam, an integrated geosynthetic release film that mitigates the risk of particle buildup by protecting the geomembrane weld edges from exposure to field conditions.

The mine upgrade is ongoing with about half of the pad complete. Thus far, the contractor has estimated that the project is more than a month ahead of schedule.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG