Company:

MakMax Australia

Project Details

Fabric 1

Soltis FT381

Producer/Manufacturer:

Serge Ferrari North America Inc.

Primary Use:

Main Fabric

Engineer Company 1

MakMax Australia

Design Company

MakMax Australia

Architect Company

Blight Rayner Architects

Fabrication Company

MakMax Australia

Subcontractor Company

Heka Group (Steel), Ozrig

Project Manager Company

MakMax Australia

Installation Company

MakMax Australia (Retractable Roof); Ozrig

Please describe the project specifications

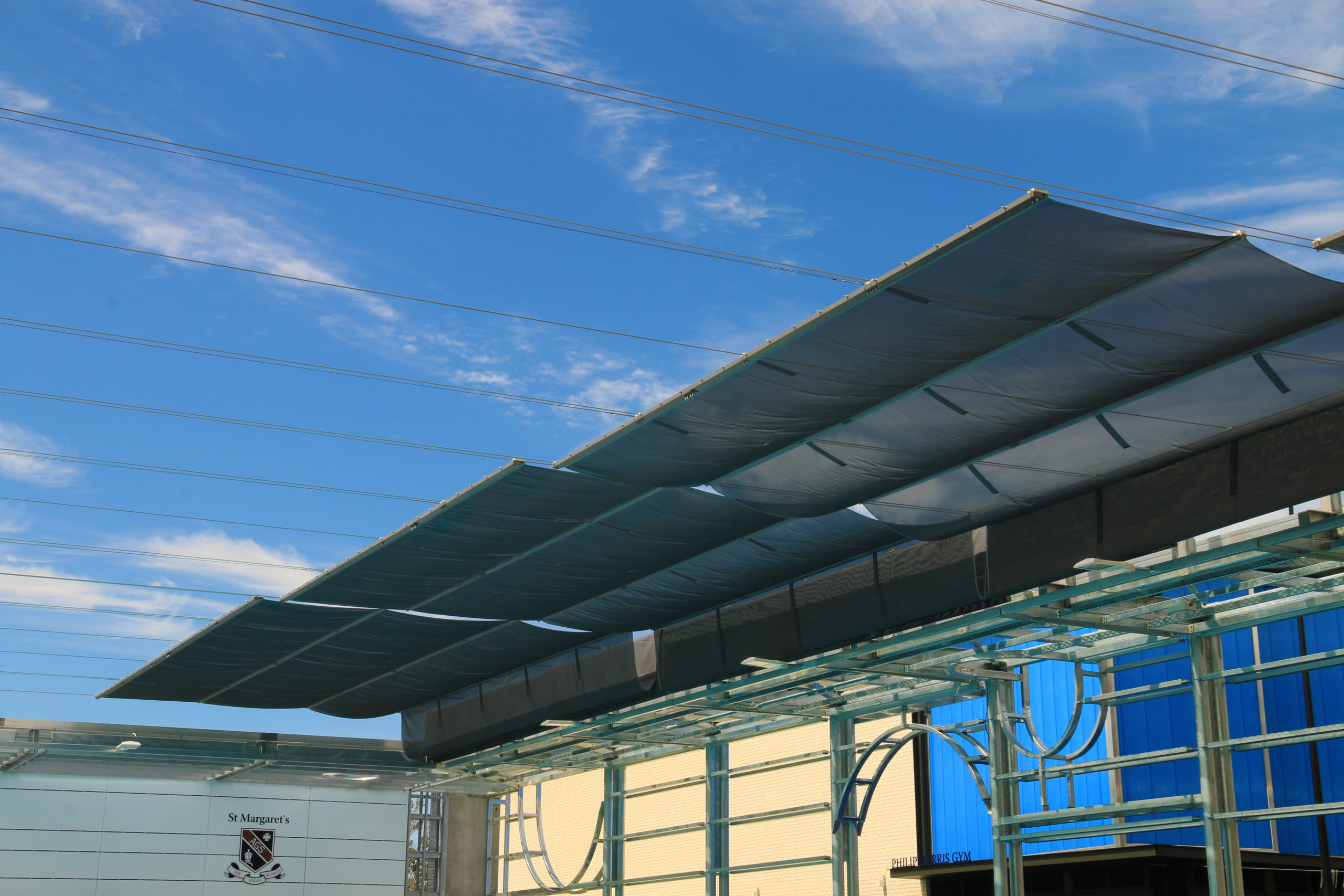

Faced with a challenge to create an innovative retractable roof for the swimming pool in the new sports precinct development for St Margaret’s Anglican School in Brisbane, Australia, we designed, engineered, developed, tested and fabricated the Velarium Variable Shade System.

The Velarium Variable Shade System at St Margaret’s allows the 4 sets of fabric shade panels to be operated with push-button controls. They can be manipulated as a whole or in individual sections, allowing for different parts of the pool area to be covered or open to the sky.

Intended to be used as sun protection while students are using the pool, the 40m x 30m space is covered by a structural grid of cables spaced at approx. 2.5m apart, which in turn support 4 opposing pairs of fully motorised fabric shade sections. The 150m2 opposing panels close from the outside, meeting in the centre.

Soltis FT381 from Serge Ferrari was chosen for the retracting roof panels. Lightweight, durable and flexible, Soltis FT381 is a high translucency PVC mesh material that allows natural light to enter, while protecting swimmers and spectators against harmful UV rays.

The premium look, as well as the high thermal and solar protection required to shade the pool area were the main reasons Serge Ferrari Soltis 381 was chosen for this project. Normally installed in tensioned applications, such as facades or static shade sails, a number of innovative components were engineered and incorporated into the fabrication stage of the St Margaret’s project in order for the shade panels to behave in their designed manor during opening, closing and in windy conditions.

A number of innovative proprietary components were incorporated into the fabric panels to stabilise the fabric folds as the individual sections concertina in and out. Particular attention was paid to leading-edge extrusions and the fabric fixing systems to avoid the slack panel sections fouling the cables while under motion, allowing them to run smoothly along the cable grid, even in high-wind conditions.

Completing the project’s low-impact visuals, the fabric panels are supported by 12mm structural cables, and the roof retraction is made possible by four 0.75kW (IP55) Electric Motors hidden in the upper steel structure. Each panel section spans 4 or 5 cables and has a leading-edge extrusion with nylon runners that attach to the main cables.

With safety at the forefront of design for education sector projects, the St Margaret’s pool roof has been engineered to withstand wind gusts of up to 125km/hr while closed, however it features a fail-safe function of automatically retracting when wind speeds rise about 27km/hr, protecting the fabric and the cabling.

The roof support-system is designed for minimal maintenance by combining corrosion resistant aluminium battens with a robust stainless-steel cable-supported operating system.

Key to the development of these innovative components was the construction of a full-size mock-up of one set of opposing fabric panels in the carpark of our fabrication facility. Extensive testing of each component and how they effected the behaviour of the fabric under motion ensured that the new system was proven in a practical way prior to the system initial installation at St Margaret’s.

What is unique or complex about the project?

Blight Rayner Architects initially approached us with a challenge to design and develop a retractable roof concept for the swimming pool in the new sports precinct development at St Margaret’s Anglican School in Brisbane.

Well known for our extensive portfolio of tensile membrane fabric structures for schools, universities and learning centres, we generally work in fixed tensile structures. The brief for the shade cover over the pool at St Margaret’s was to optimise the operational costs and seasonal flexibility by controlling the levels of sunshine onto the pool’s surface. This was to be achieved with a series of motorised mesh fabric panels that could open and close at the push of a button.

Our engineering team relish design challenges like this. Being designer-builders, we had the ability to design, test, check and refine our ideas to ensure what came to site would work as intended. Complexities of high cable loads, precambering of steelwork and specific erection sequences were all coordinated with the head contractor and our partner subbies. Our extensive education experience means the design always progressed to best meet the school’s needs and operational requirements.

The result of the project is the Velarium Variable Shade System, which can now be customised and adapted to suit future projects.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG