Company:

Signature Structures

Project Details

Fabric 1

Ferrari 702

Producer/Manufacturer:

Serge Ferrari North America Inc.

Primary Use:

Main Fabric

Engineer Name 1

Dirk Cos

Engineer Company 1

Lightweight Design

Design Name

N/A

Design Company

N/A

Architect Name

N/A

Architect Company

N/A

Fabrication Name

Signature Structures

Fabrication Company

Signature Structures

Subcontractor Name

N/A

Subcontractor Company

N/A

Graphics Name

N/A

Graphics Company

N/A

Project Manager Name

Curtis Mita

Project Manager Company

Signature Structures

Installation Name

Signature Structures

Installation Company

Signature Structures

Please describe the project specifications

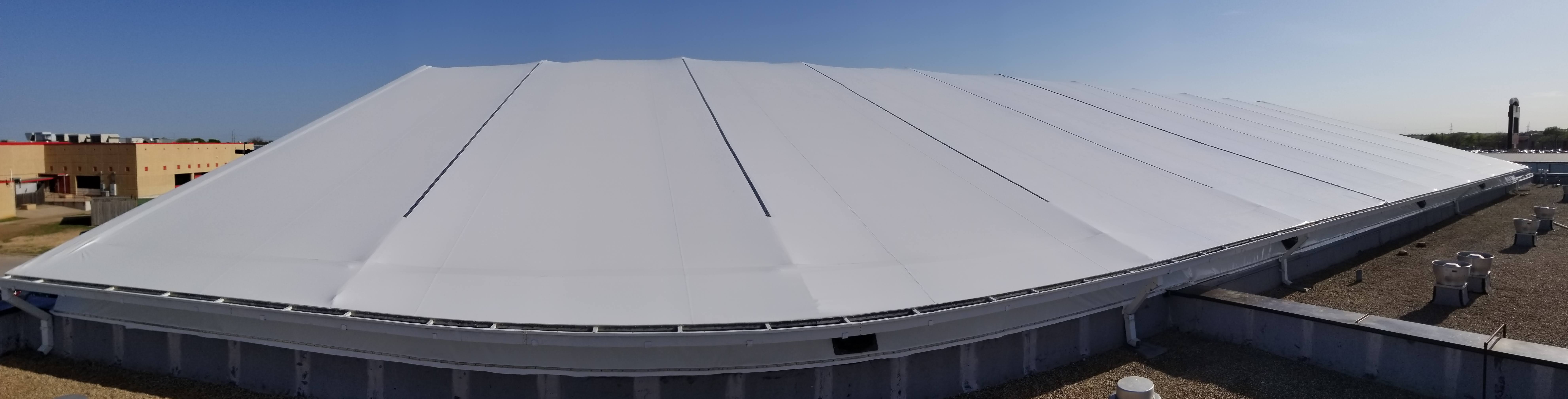

Client Request: Client had purchased a tension fabric structure in the mid-90s from a company that has since gone out of business. The HDPE membrane on the structure was failing rapidly and needed to be replaced. A storm has torn parts of the roof open and damaged the insulation underneath.

Solution: The structure presented unique challenges because it was a custom design that connected on two sides to conventional brick and mortar buildings. There were no existing drawings that could be located and used to design the new membrane cover. Our company and its design/engineering partner were able to reverse engineer the cover through the use of extensive surveys and measurements along with visual inspections performed when we performed emergency repair work.

The redesigned cover was installed using our unique over-the-top membrane refurbishment system with an all new fabric attachment and tensioning system that allowed the entire refurbishment to be performed with virtually no interruption of activities inside the building. We also repaired the damaged insulation.

Tension fabric indoor pool enclosure part of an aquatic complex owned by the Belton ISD in Texas

built in mid-90s

fabric damaged to due age and degradation

Connected to multiple conventional structures.

What is unique or complex about the project?

The Belton ISD turned to our company when storm had damaged the roof and damaged the insulation. Despite being located nearly 1,500 miles away, we were able to dispatch technicians and materials rapidly to fix the damage. When the determination was made to refurbish the complete membrane system, we were brought aboard.

We are accustomed to having to do complete redesigns without the benefit of original drawings. Even so, this was a very challenging project due to large number of custom elements including multiple structural interfaces, overhanging eaves, and gutter systems attached to the structure.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG