Company:

Beijing N&L Fabric Technology Co., Ltd.

Project Details

Fabric 1

Soltis SK20-Xtra LowE

Producer/Manufacturer:

Serge Ferrari North America Inc.

Primary Use:

Main Fabric

Fabric 2

PTFE T300

Producer/Manufacturer:

OTHER

Primary Use:

Main Fabric

Engineer Name 1

Zhang Wenying

Engineer Company 1

Beijing N&L Fabric Technology Co., Ltd.

Architect Name

Zheng Fang

Architect Company

Beijing Architecture Design & Research Group

Fabrication Name

Wu Huaisheng

Fabrication Company

Beijing N&L Fabric Technology Co., Ltd.

Graphics Name

Zhang Wenying, Xiao Jinsong, Li Gaoyang

Graphics Company

Beijing N&L Fabric Technology Co., Ltd.

Project Manager Name

Wu Binhong

Project Manager Company

Beijing N&L Fabric Technology Co., Ltd.

Installation Name

Wu Binhong, Jin Xiaofeng

Installation Company

Beijing N&L Fabric Technology Co., Ltd.

Please describe the project specifications

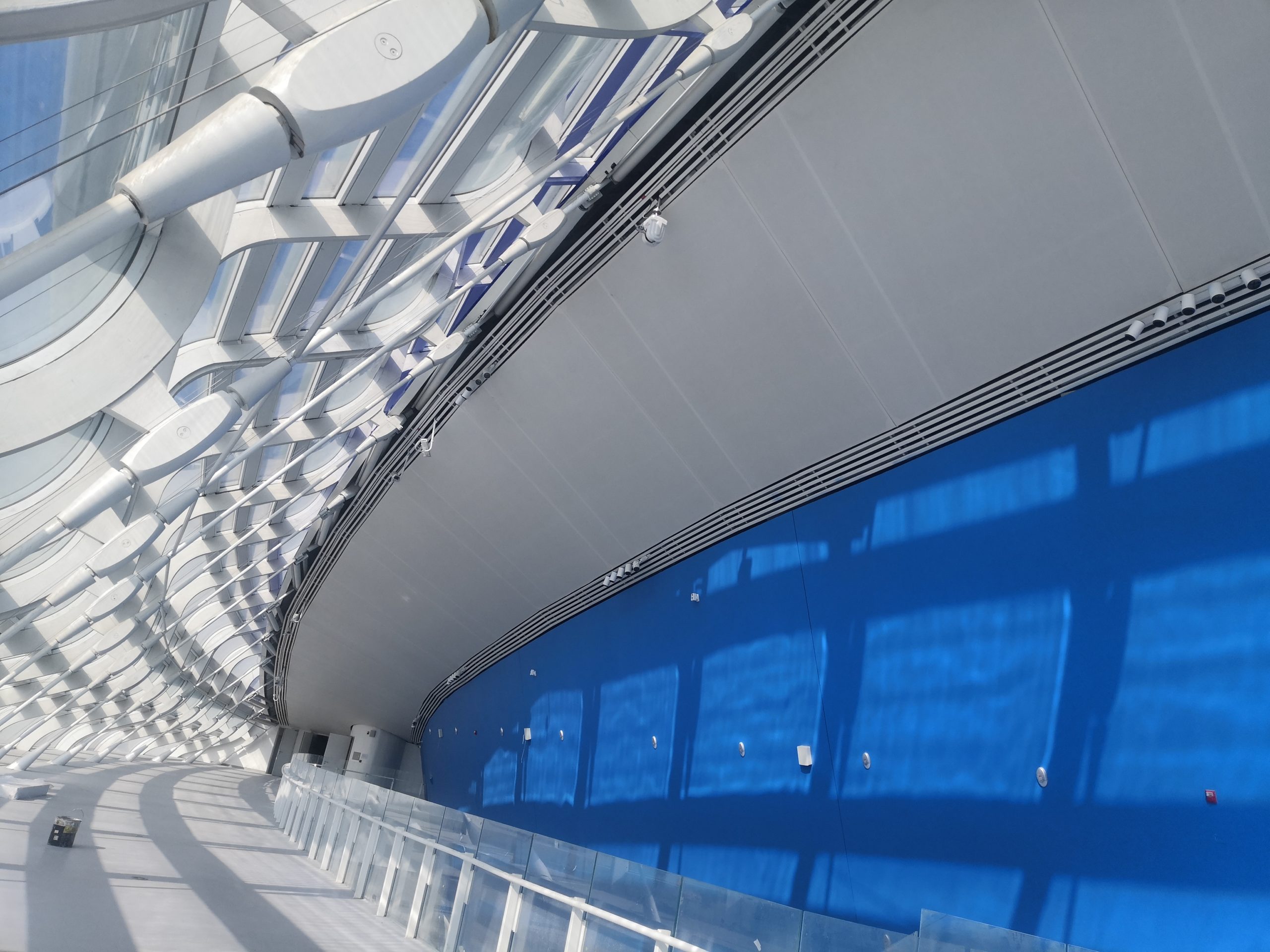

The National Speed Skating Oval is the only newly-built venue in Beijing for the 2022 Winter Olympics. Building long axis is about 240m; short axis is about 176m and the highest point is 33.8m. Roof main structure system is saddle-shaped single-layer cable net and its periphery is circular steel truss structure.

The National Speed Skating Oval Membrane Ceiling project is the interior decoration system of roof main structure system. It consists of three parts: the first part is audience lounge glass fiber film (PTFE), membrane surface area is 3,925 m²; the second part is competition hall glass fiber film (PTFE), membrane surface area is 6,262 m²; the third part is sound absorption ceiling membrane of the competition hall. It is above the competition hall and below the main cable net system, membrane projection area is 18,723 m² and surface area is 21,644 m².

This project is the training and competition venue of speed skating sports in Beijing for the 2022 Winter Olympics. This membrane structure, firstly, shall meet continuous and aesthetic requirements of hyperbolic membrane ceiling; secondly, membrane ceiling shall meet function requirements for thermal protection, heat insulation (thermal radiation rate is less than 0.3, reflection rate is greater than 60%) and sound absorption (noise reduction coefficient-NRC is above 0.9); thirdly,need a large number of hanging points bearing 800kg to7500kg in sound absorption ceiling area; finally, membrane materials must be Class A fire resistance.

What is unique or complex about the project?

We are experienced in membrane (PTFE, ETFE, and PVC etc.) and cable structures, and have completed many large-scale membrane structure projects, including: National Stadium (Bird's Nest), Foshan Century Lotus Sport Center Stadium, Jomo Kenyatta International Airport Expansion & Renovation Project, Qingdao Etsong Stadium and so on. Our excellent services and skilled technology make our projects won many prizes both at home and abroad.

Soltis SK20-Xtra LowE membrane materials are fragile. They must be carefully treated during fabrication, packing, on-site hoisting and installation, so high efficient team management and skilled workers are very important for this project.

With the goal of energy-saving design and achieving expected architectural effect, this membrane structure shall meet many technical requirements like thermal protection, heat insulation, sound absorption, load-bearing hanging points and Class A fire resistance membrane materials.

It is the first case to adopt Soltis SK20-Xtra LowE membrane materials combined with sound absorption cotton as a membrane ceiling in China. The membrane ceiling is formed by putting 50 mm glass fiber water repellency and sound absorption cotton above LowE coating membrane materials, and cavity is more than 100mm. This new materials combination can isolate heat from roof and deliver very little heat to ice (as low as 0.25) and also make ice itself reflect cold thermal radiation back to ice surface (reflection rate is 70%), thus maintaining ice at low temperature and greatly saving energy. Noise reduction coefficient (NRC) of this membrane ceiling is up to 0.95.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG