Company:

MakMax Australia

Project Details

Fabric 1

AGC Fluon ETFE Film

Producer/Manufacturer:

OTHER

Primary Use:

Main Fabric

Engineer Company 1

MakMax Australia

Architect Company

BNMH; architectus

Fabrication Company

MakMax Australia; Shanghai Taiyo Kogyo

Subcontractor Company

JG Vertical, Bruce Clarkson

Project Manager Company

MakMax Australia

Installation Company

Architectural Membrane & Rigging PTY LTD

Please describe the project specifications

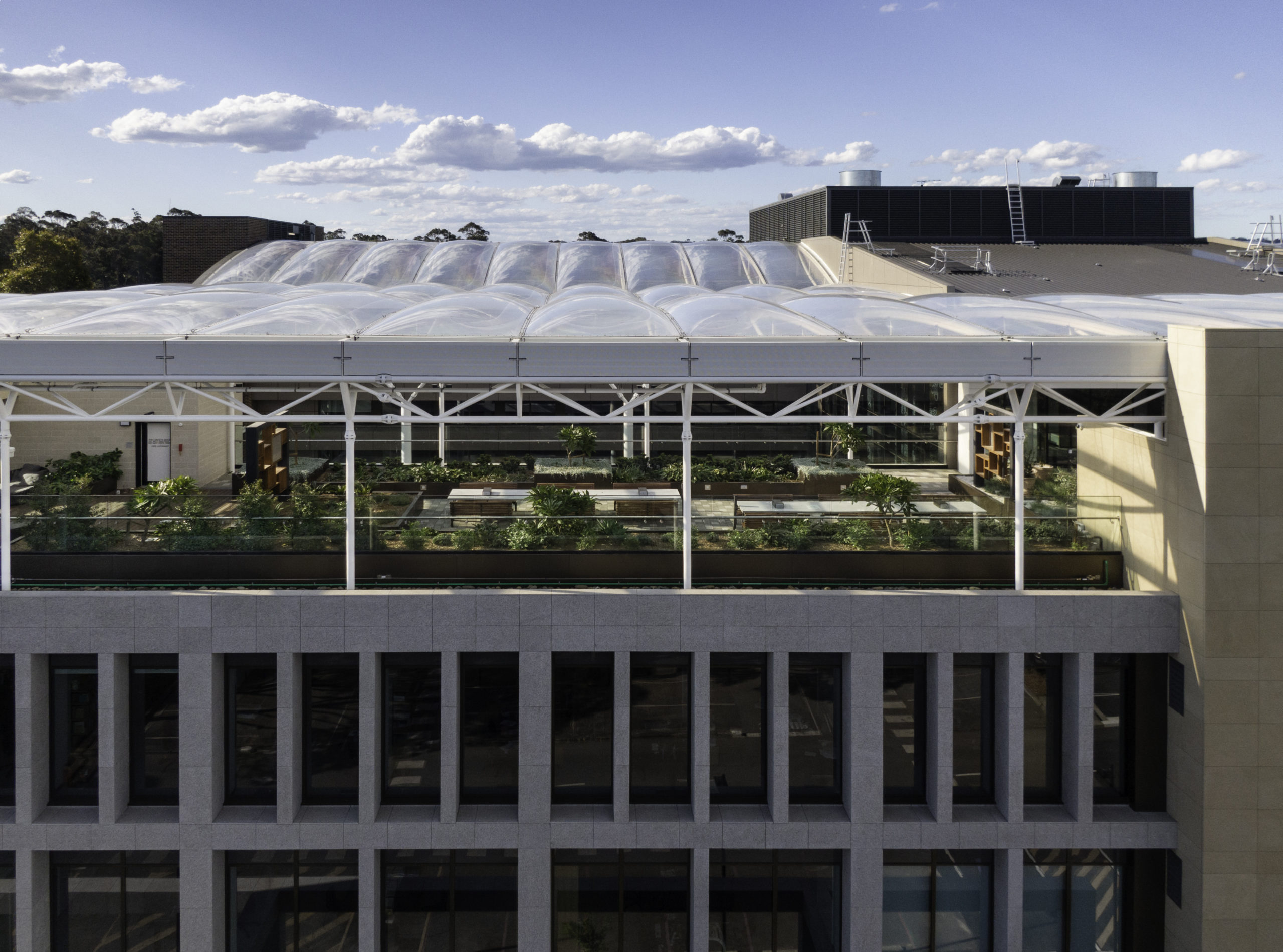

A modern, lightweight, translucent roof connects the Macquarie University Arts Precinct buildings. The 2-layer, air-inflated ETFE roof covers the top floor roof gardens of two buildings and forms an internal atrium in the middle of the arts precinct.

The overall project design is intended to allow a large amount of natural light through into the deep atrium, ensuring that the ground level plaza spaces feel bright and airy.

At the upper terrace levels, the building design called for a light-filled terrace with plants and vegetation to provide an internal garden space for students and faculty. The use of ETFE foil as a roofing material, providing excellent light transmission and transparency to UV is perfect for this brief.

The primary structural engineer, in conjunction with the project architect, had designed highly aesthetic, lightweight cigar trusses to span the open atrium space. The major truss elements also include reticulated roof-water drainage through box gutters. Integrating our proprietary ETFE extrusion systems into these cigar trusses in a manner that did not detract from the architectural intent, was a key challenge and required the design and development of a non-standard fixing detail.

For this project a clear ETFE film, Japanese-made AGC Fluon®, was chosen to fulfill the brief. Our team undertook detailed analysis to specify the required foil thicknesses for the site wind-speeds, relying on wind tunnel testing to evaluate the peak pressure loads. Using advanced form finding techniques, the 2D shapes required to create the 3D cushions were designed and sent to our factory where the final 2-layer foil sections could be fabricated.

The cushions themselves are supported by one of our proprietary aluminium extrusion systems, with an integrated gasket clamping system to maintain pressure and water tightness at all joints.

The ETFE cushions are kept inflated with a Elnic pressure control system, capable of supplying up to 1400m3/h of pressurised air. The air-blower unit includes 2 independent running fans for redundancy, adsorption dryers (dehumidifier), air intake filtration system, remote monitoring and control system and integration into building’s climate control management system.

Keeping air supply lines as unobtrusive as possible was a key architectural requirement, which required a lot of thought due to the large roof coverage and few areas to hide service conduits. A complex air distribution piping network had to be designed, giving special attention to the location of pressure monitoring sensors within the conduit system.

What is unique or complex about the project?

Growing in popularity in Australia, the use of ETFE is what attracted us to this project. The Macquarie University Arts Precinct ETFE roof is an incredibly light structure, that thanks to its transparency, enhances the other elements of the building, such as the stunning roof garden and open-air atrium.

The whole build was delivered with an extremely high standard and the ETFE roof looks like a floating crown, capping off a modern, architecturally unique arts precinct. We are delighted to have been involved in this fantastic project.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG