Company:

JAKs Awnings Ltd T A Cool Awnings

Project Details

Fabric 1

Diamond 700 PVC Translucent

Producer/Manufacturer:

Contender NZ Ltd.

Primary Use:

Main Fabric

Installation Company

JAKs Awnings Ltd T A Cool Awnings

Please describe the project specifications

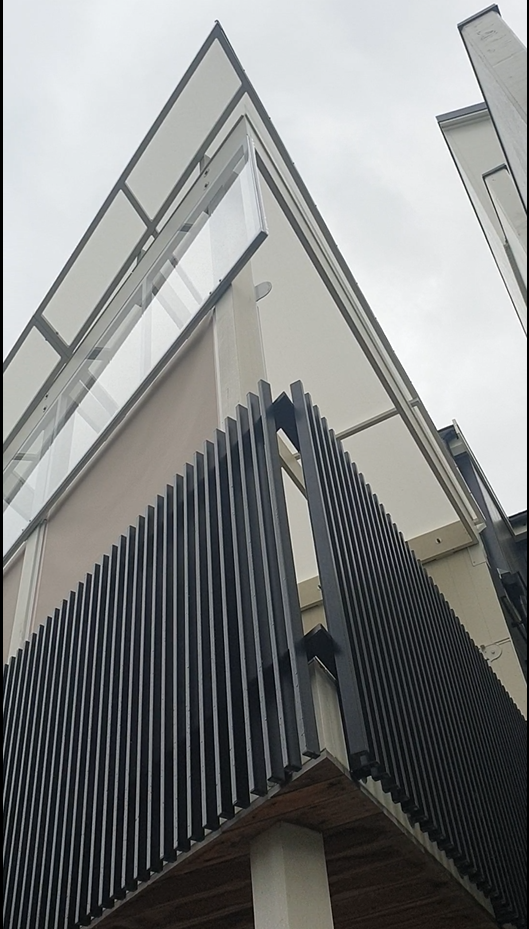

We were asked to cover an architecturally designed, first floor deck, which currently housed a rhomboid shape pergola. The customer wanted to cover the pergola with a waterproof canopy which sat above the structure, overhung on two sides and shed rain back towards the house.

The customer came into the office with his drawings and spent a long time with us talking over the options. As an architect, he had very specific requirements for the design. Customer wanted the frame to sit high on the pergola on two sides, overhang front and one side by 300mm, and wanted us to fill the gaps that would be left around the frame with a combination of flashings and infill panels.

The customer also requested the canopy would fall back towards the house and not shed off the side where the neighbors are (so it didn’t annoy them).

What is unique or complex about the project?

There was only one 90 degree angle on the roof, and it was difficult to get an accurate measure with two corners finishing up in the air. We had to draft it up to get the correct design

The only access was through the building and up the stairs as the apartments were all joined together and we could not get the vehicle the back of the property. There was not enough maneuvering space onsite to make this as a kit set, so we made it in two sections, that would be bolted and sealed together.

We tacked together the base frame in two pieces and took it to site for a test fit.

With a couple of tweaks, manufacturing was completed, and it was powder coated and covered in store, then the two sections were installed onsite.

The install began with installing the support brackets that we made, then the back section was lifted and bolted into place. The front section, was then lifted and joined to the back and bolted to the brackets.

Once the roof had been installed we measured for the infill panels around two sides and for the flashings that were required to close the gaps.

These we also test fitted, then manufactured and installed to complete the roof installation.

Customer is an architect and was eager to get involved, and give suggestions at every stage of the test visits and installations. It wasn’t until after we started the installation that the customer let on he had approached several other companies who had said they couldn’t help.

The customer very happy with the final result. We also supplied and installed blinds around the structure to allow year round use of the space.

Content is submitted by the participant. ATA is not responsible for the content descriptions of the IAA award winners.

John Glenn

John Glenn

John Glenn

John Glenn

TEXTILES.ORG

TEXTILES.ORG