Company:

Shanghai Taiyo Kogyo Co. Ltd. Shanghai,

Project Details

Fabric 1

ETFE

Producer:

AGC

Supplier:

AGC

Architect Company

Masters Architectural Office

Fabrication Company

Shanghai Taiyo Kogyo Co. Ltd.

Graphics Company

Zhang, Ying

Project Manager Company

Zhou, Wengang

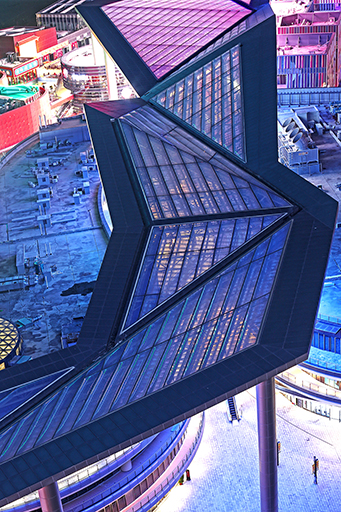

Please describe the project specifications

The large-scale commercial skylight project, Shimao International Plaza phase I, using a new design of the membrane structure to create the first block of the Dream Street in the region. It is divided into two areas: the north and south, and the upper layer is composed of about 406 strips and trapezoidal ETFE cushions. The height of the canopy structure is 69.4 meters and the minimum elevation is 49.9 meters. Covers an area of about 12,000 square meters. The entire system is light and elegant. When it is in the hot sun, it can be insulated and protected against radiation. When weather is bad, it can shelter wind and rain. And the projection effect of the sky screen itself has a wonderful artistic outlook. Whether it is flying the sky, walking the universe or the image display of natural scenery, it can bring the ultimate visual effect, unparalleled international metropolis experience, and create a good leisure.

What was the purpose of this project? What did the client request?

To create the world's longest skylight with a length of 532 meters and bring audiences into a space of unlimited imagination with a variety of three-dimensional effects of sound, light, electricity. Using Internet to generate an interaction between people and the canopy. At the same time, the canopy can also be a huge landmark of city, greatly increase the visibility of the project and create topics in the crowd to be the focal point of the Shishi city.

What is unique or complex about the project?

The key difficulties of this project is with following 3 aspects: First, adopting 3D cutting to achieve the actually necessary arching height to meet the requirements of special coastal area load and drainage; Second, the resolution and management of steel fabrication tolerance; Third, safety and waterproofness of fixing joints; Fourth, the difficulty of installation.

What were the results of the project?

Another successful large scale ETFE project we completed with a perfect result. The client was extremely pleased with our work. The structure was part of one of the tightest construction sites we’ve ever worked in.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG