Company:

Sand Sea & Air Interiors Inc. San Juan, PR

Project Details

Fabric 1

OTHER

Producer:

OTHER

Supplier:

OTHER

Design Name

Mary McClug

Fabrication Name

Sand Sea and Air Interiors

Fabrication Company

Sand Sea and Air Interiors

Project Manager Name

Romeo Tecu Tecu

Project Manager Company

Sand Sea and Air Interiors

Installation Name

Custom Contour Valances

Installation Company

Sand Sea and Air Interiors

Please describe the project specifications

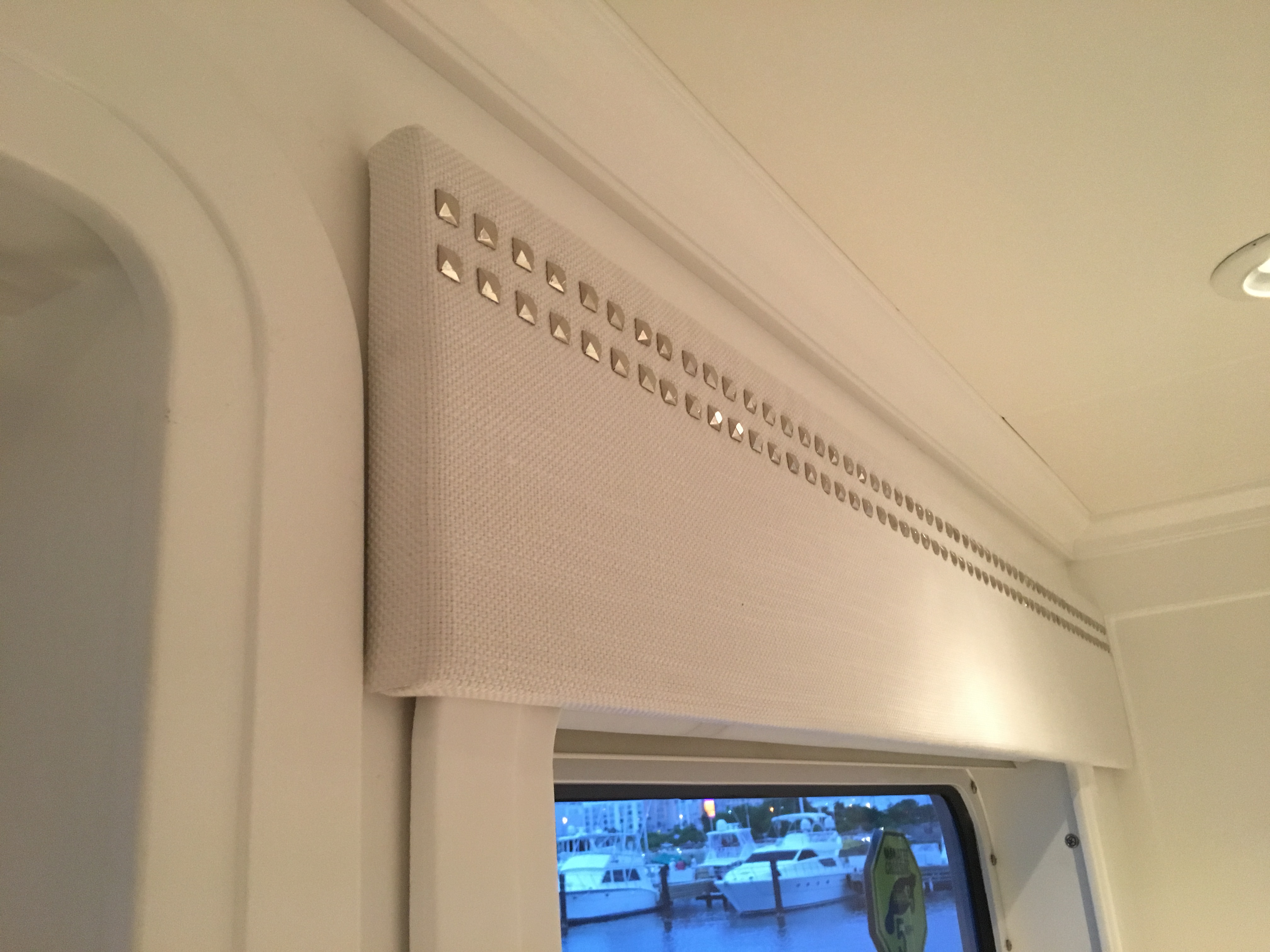

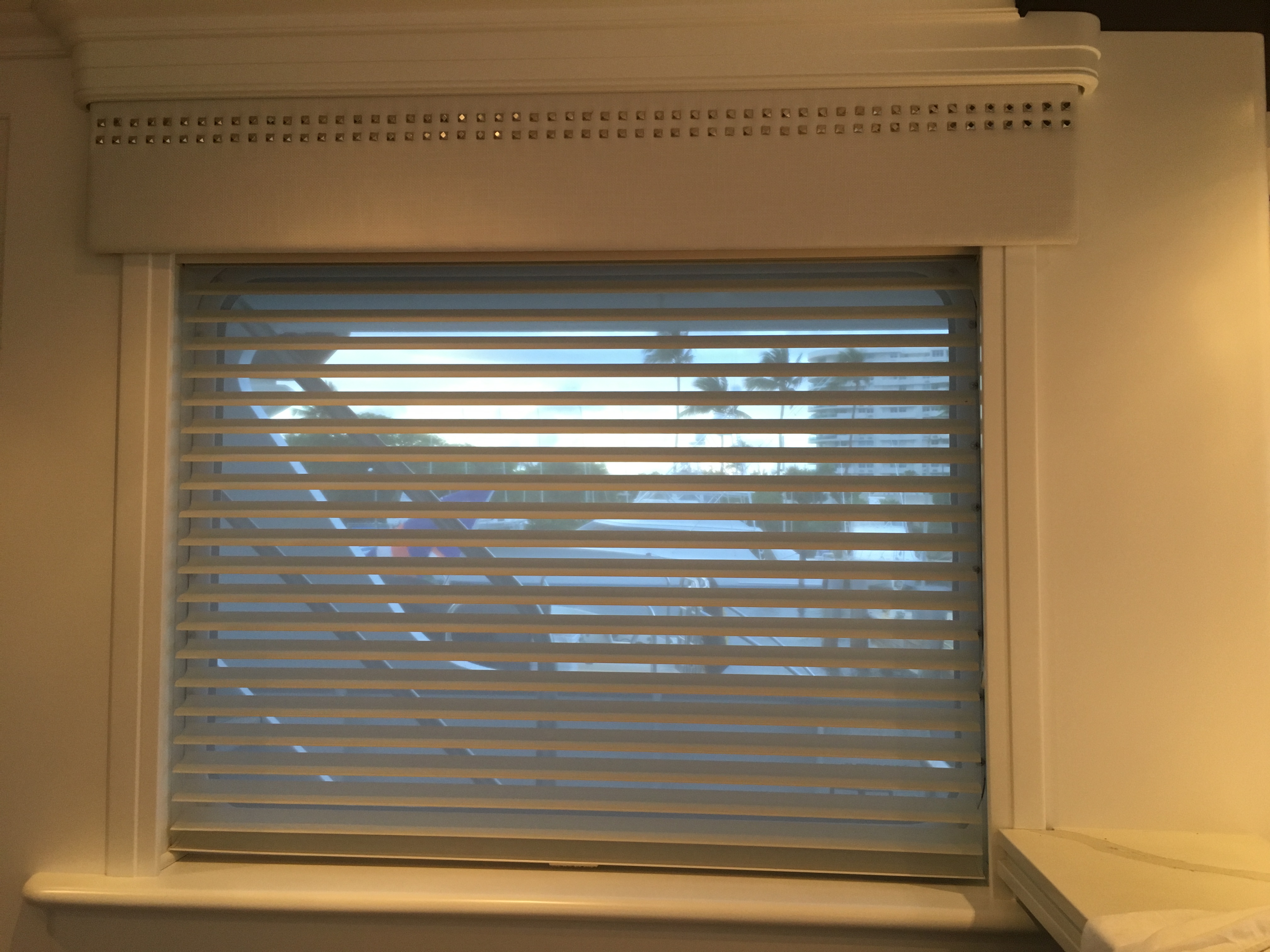

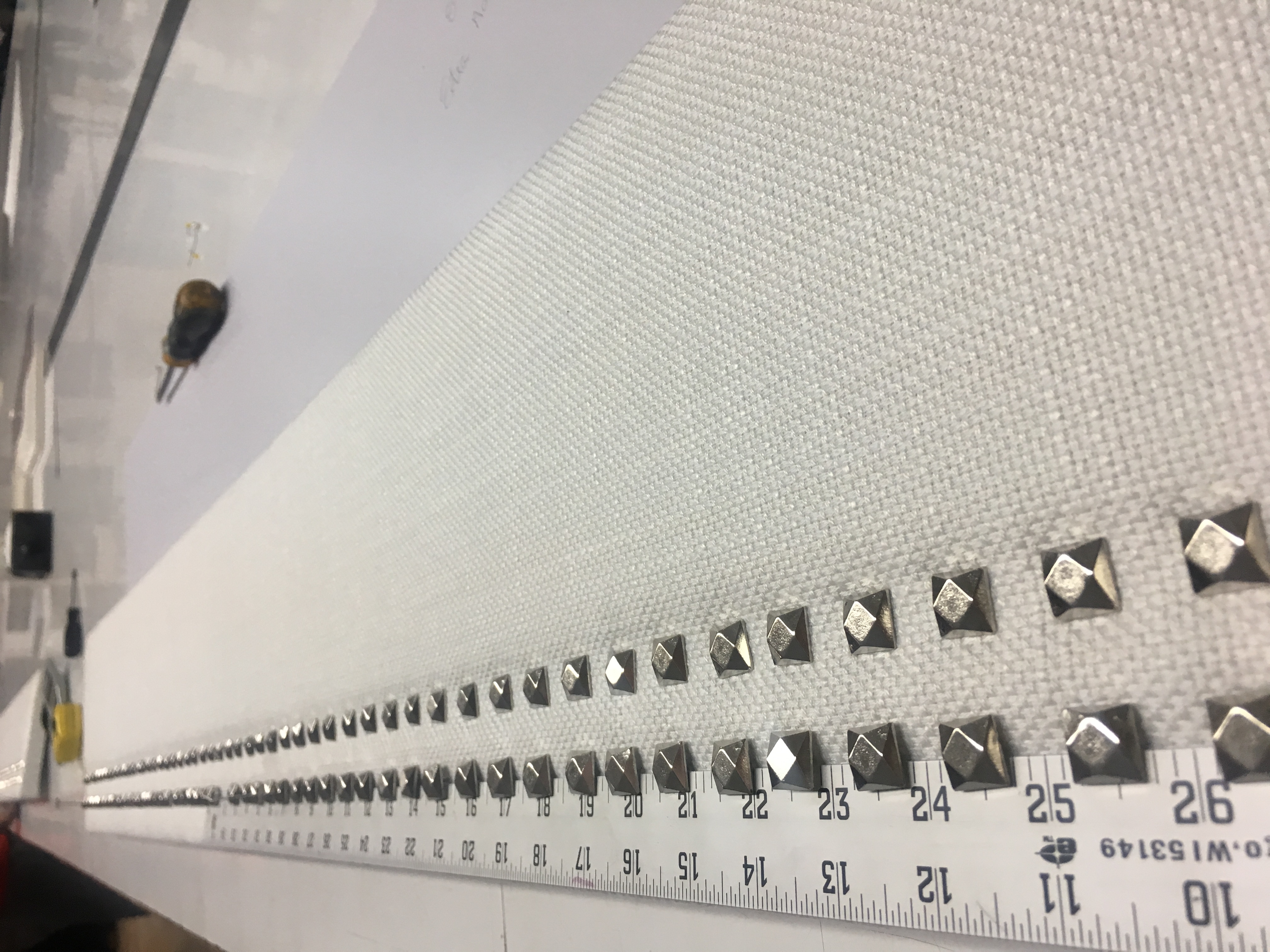

Five custom window valances were crafted for the interior of a luxury expedition yacht. The structure of the valances was composed of two 1/4” PVC panels glued together with 1/4” foam backing. Due to the variety in both size and style of the 5 window areas throughout the saloon, the design of each valence was elaborated to accommodate these differences while composing a unified look. Vessel measurements required the valances to protrude a maximum of 3/4” from the walls, and to occupy a maximum visual height of 8.5”, with the longest panel being over 13” in length. Two rows of decorative 1/2” square nickel nail heads were chosen to accent each valance, of which 900 were utilized in total that demanded meticulous attention to detail over the exquisite weave of a Casamance textile.

What was the purpose of this project? What did the client request?

The owner was very specific in her request, she actually knew exactly what she wanted though needed us to compliment and execute her vision.The client was interested in creating a sleek and cohesive atmosphere for their refurbished saloon.

The owner wanted one last touch…a unifying feature for the vessel’s updated appearance of custom window valances on areas above the windows that were nonexistent in a material that complemented the main saloon.

What is unique or complex about the project?

The 5 window areas had severe irregularities in the wall and diverse measurements. Each window required the placement of the custom valances to be carefully planned. To create a harmonized look that actually hid all of the window irregularities and added to the ambience of the saloon. Throughout the saloon there were accents of polished aluminum marine hardware on the vessel and this was the inspiration for the selected nail head detail to be installed on the valances. As a accent we were requested to install 2 parallel rows of nail heads. Due to the inconsistencies in height and length of the walls we had to compensate for this when installing the 850+ custom-spaced nail heads by hand. We used a laser to visually align and account for the distortion produced by the angles the structure was constructed on.

What were the results of the project?

A flush mount installation using the Fastmount panel mounting system provided a visually fluid eye appealing unity to the Salon. Our calculations ensured that from every perspective, the detail was harmonious to the eye. Our design contributed to the coherence of our client’s aesthetic vision.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG