Company:

Sand Sea & Air Interiors Inc. San Juan, PR

Project Details

Fabrication Name

Sand Sea and Air Interiors

Fabrication Company

Sand Sea and Air Interiors

Project Manager Name

Terri Madden

Project Manager Company

Sand Sea and Air Interiors

Please describe the project specifications

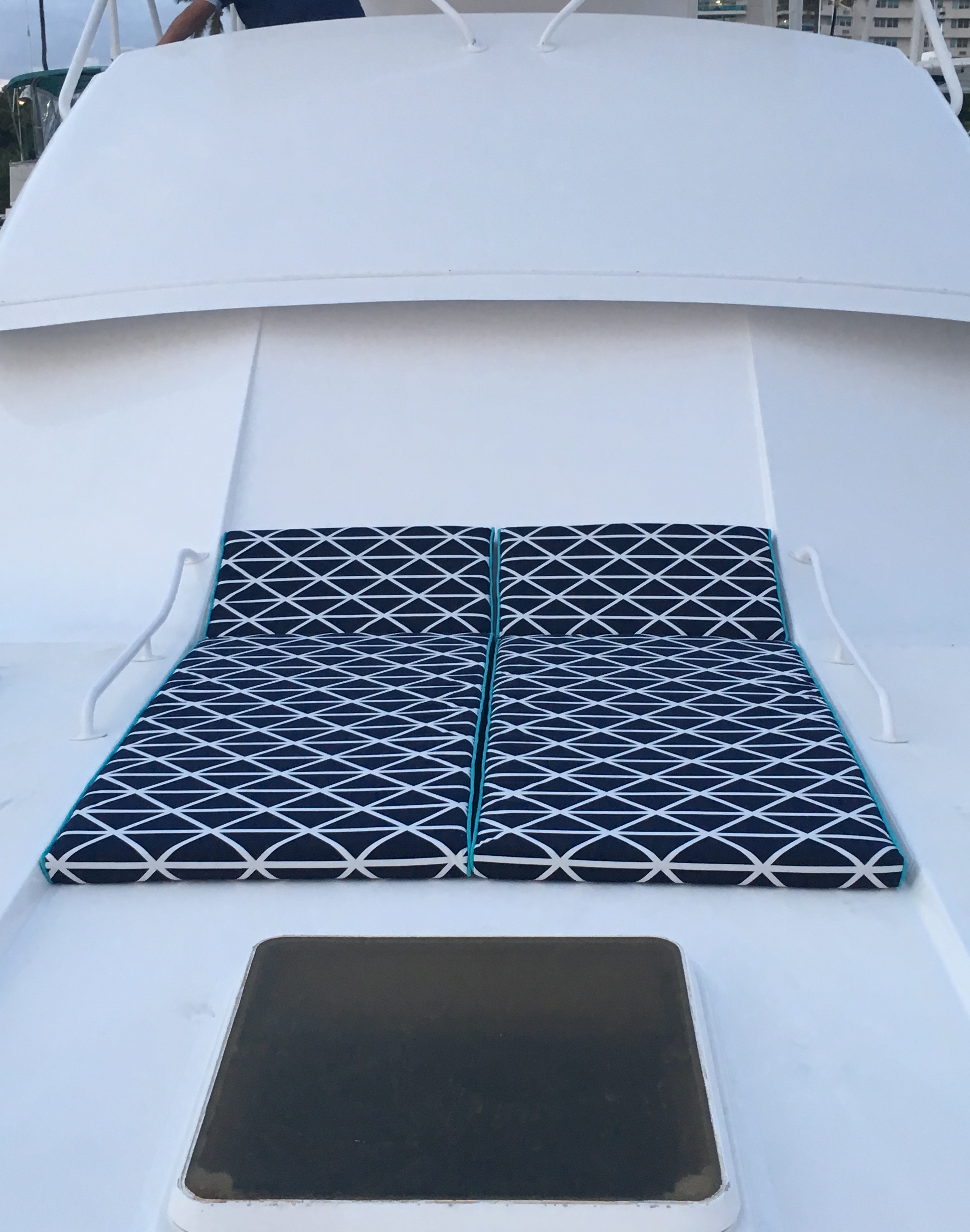

This commission for a 1990 Betram 50’ included two Pilot seat & back cushions, Bridge seat & back cushions, with 2 Sun Pad on the bow of the vessel. All pieces were crafted in an exterior marine fabric of a white and navy geometric textile with a solid navy banding & contrast aqua piping. The accent pillows were done in the reverse colors. All items were were sewn with PTFE thread and fitted with 2” DryFast foam, YKK marine zippers, as well as marine polyester velcro and stainless steel snaps. Bridge seating and sun pad cushions feature intricate pattern matching for adjoining pieces; especially the hinge bow cushions. All seating has Textilene mesh bottoms with a zipper closures.

What was the purpose of this project? What did the client request?

This project was part of a reupholstery that aimed to transform the look of the 20+ yr old yacht. The client was interested in creating a new atmosphere with colors allusive to the marine elements, and in the striking statement of a geometric pattern. The new design had to be cohesive with the pilot seat’s armrest, which the client desired to keep unchanged.

What is unique or complex about the project?

The bridge seating we provided was manufactured completely new from custom patterns. Since the seating space was curved in the back, careful planning had to go into matching the selected fabric’s pattern from the back cushions to the seat cushions.

The sun pad presented an similar challenge. Its back cushions lay on a bevel with curved sides. We attended scrupulously to measurements in order to match the bold pattern throughout all cushions while accounting for changes in angle and the aqua border between cushions.

The pilot seat also visually accommodated the pattern into two high-low contour seams, made to fit the foam’s construction in order to cradle the pilot’s back.

What were the results of the project?

Our attention to detail accomplished a perfect pattern match across all articles, compensating for special seams and measurements. The client’s vessel was left with a crisp finish reminiscent of life in the islands.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG