Company:

ARTech, Div. of A&R Tarpaulins Inc. Fontana, CA

Project Details

Fabric 1

MD3 CTR

Producer:

Saint-Gobain Technical Fabrics

Supplier:

Saint-Gobain Technical Fabrics

Project Manager Name

Jessica Foley

Project Manager Company

A&R Tarpaulins. Inc

Please describe the project specifications

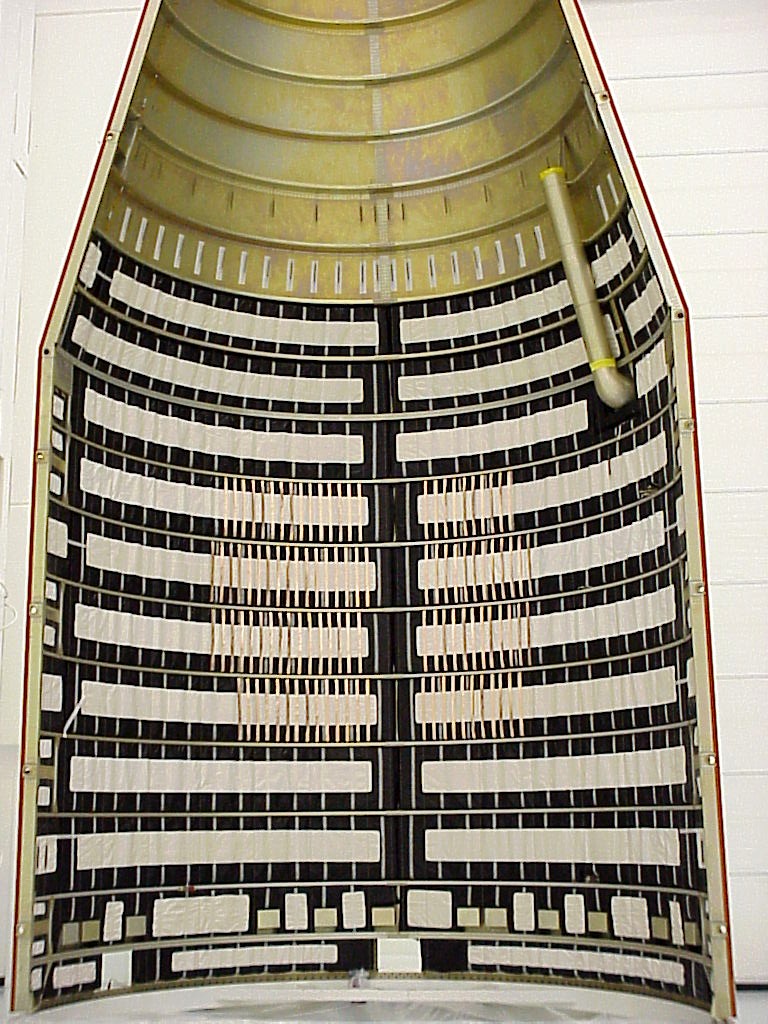

These blankets are used to line the PayLoad Fairing (or nose cone) of a space launch vehicle. They provide sound absorption and vibration reduction, static bleed off with carbon Teflon cover material, and ensuring that particles from the interior of the blanket do not contaminate the satellite by use of the stainless steel fabric filtration medium, which also allows the blanket to expel interior pressure during launch.

Depending on the PLF configuration, there are approximately forty blankets per launch, and the blankets vary in size from 14' length x 19" wide x 3" thick to 12" length x 19" wide x 3" thick.

What was the purpose of this project? What did the client request?

PLF blankets are installed inside of the Payload Fairing of space craft. During the launch process, the rocket experiences extreme high temperatures and vibrations and the PLF blankets provide protection for the satellite during the launch as describe above.

What is unique or complex about the project?

AR Tech has been crafting thousands of these custom PLF/acoustic blankets for various launch vehicles since the 1990's. However, our client recently changed one of the key elements of the raw materials. In the past we used either 1'' or 2'' foam panels to create 3'' thickness of blankets by stacking them together, but current designs call for the use of a single piece of three inch foam to create multiple configurations of these parts. This change was a bit challenging during manufacturing due to the complicated shapes. While several vendors declined to bid for this due to the challenges of the new design, AR Tech opted to not out-source the foam cutting process and decided to utilize the talent and experience of seasoned AR Tech technical production team to accomplish this task.

What were the results of the project?

The first ship set was delivered to the customer ahead of the schedule as well as passing with 100% quality. We continue to support the customer as they are again exploring new designs.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG