Company:

Fabritecture (UFS Australasia Pty Ltd T/A Fabritecture) Varsity Lakes, Queensland

Project Details

Fabric 1

Sky Top FGT-800

Producer:

Chukoh Chemical Industries Ltd.

Supplier:

Chukoh Chemical Industries Ltd.

Fabric 2

-- Select a Name --

Producer:

Engineer Company 1

Greenup Design International

Design Company

Conrad Gargett

Architect Company

Conrad Gargett

Fabrication Company

Pfiefer Covertex

Subcontractor Company

Fabritecture Australia Pty Ltd

Project Manager Company

Fabritecture Australia Pty Ltd

Installation Company

Fabritecture Australia Pty Ltd

Please describe the project specifications

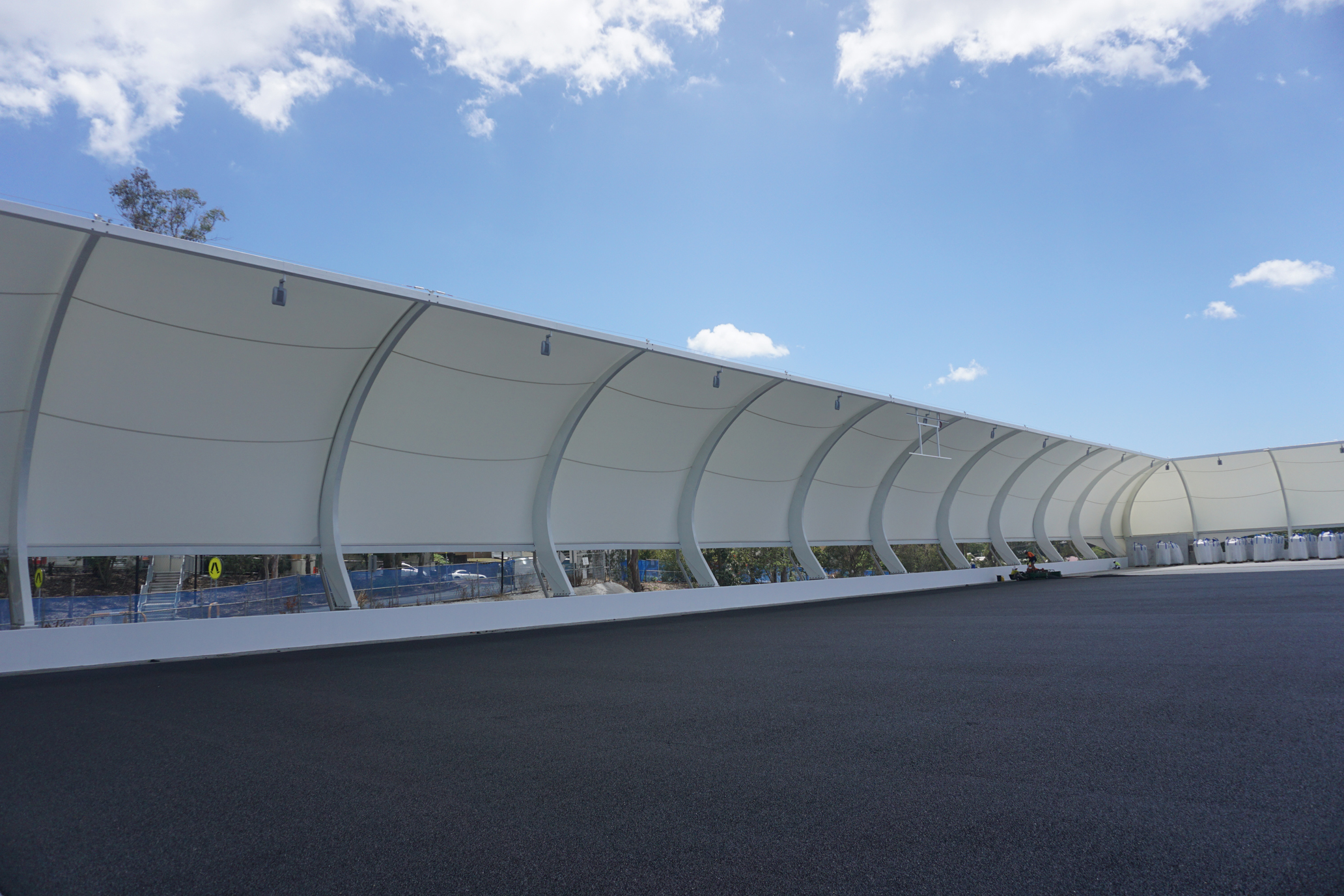

The Queensland University of Technology (QUT) Sportsfield Car Park project was part of the construction of a $27 million multi-story car park at the QUT Kelvin Grove campus in Brisbane. The scope of the project was a design and construct contract for the project contractor, ADCO Constructions.

The roof-level is home to a FIFA accredited sports field, developed as part of the long-term expansion plans for the University.

What was the purpose of this project? What did the client request?

The top-level sportsfield is an artificially turfed soccer field complete with patron viewing areas and adjacent amenities. The PTFE membrane acts as a windbreak to the patron grandstands and playing field atop the car park.

The project was developed as an aesthetic shade-and-wind barrier for the top level of the new multi-story car park.

What is unique or complex about the project?

800m2 of stainless steel fall arrest wire mesh was used around the base of the structure. The mesh was designed as a safety mechanism to ensure no one could pass through the gap, while strategically allowing airflow into the area.

Site access was limited due to the nature of the site, so installation required specific coordination to resolve this issue. Our site crew positively overcame access issues, using 4T spidar cranes supported from the slab within the building during construction.

What were the results of the project?

The client was really pleased with the result of the project. The steel ribbing of the structure was value-engineered to decrease the overall weight of the structure. The fabric portion of installation was also value-engineered, enabling us to decrease the amount of fabric required, thereby decreasing installation costs.

The problem-solving attitude of the project management team and installation crew, coupled with the successful installation of the structure has cemented a positive relationship with the client and potential future business on the horizon.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG