Company:

TenCate Geosynthetics Americas Pendergrass, GA

Project Details

Fabric 1

Mirafi

Producer:

TenCate Geosynthetics

Supplier:

TenCate Geosynthetics Asia

Fabrication Company

TenCate Geosynthetics

Project Manager Company

Grantop Group

Please describe the project specifications

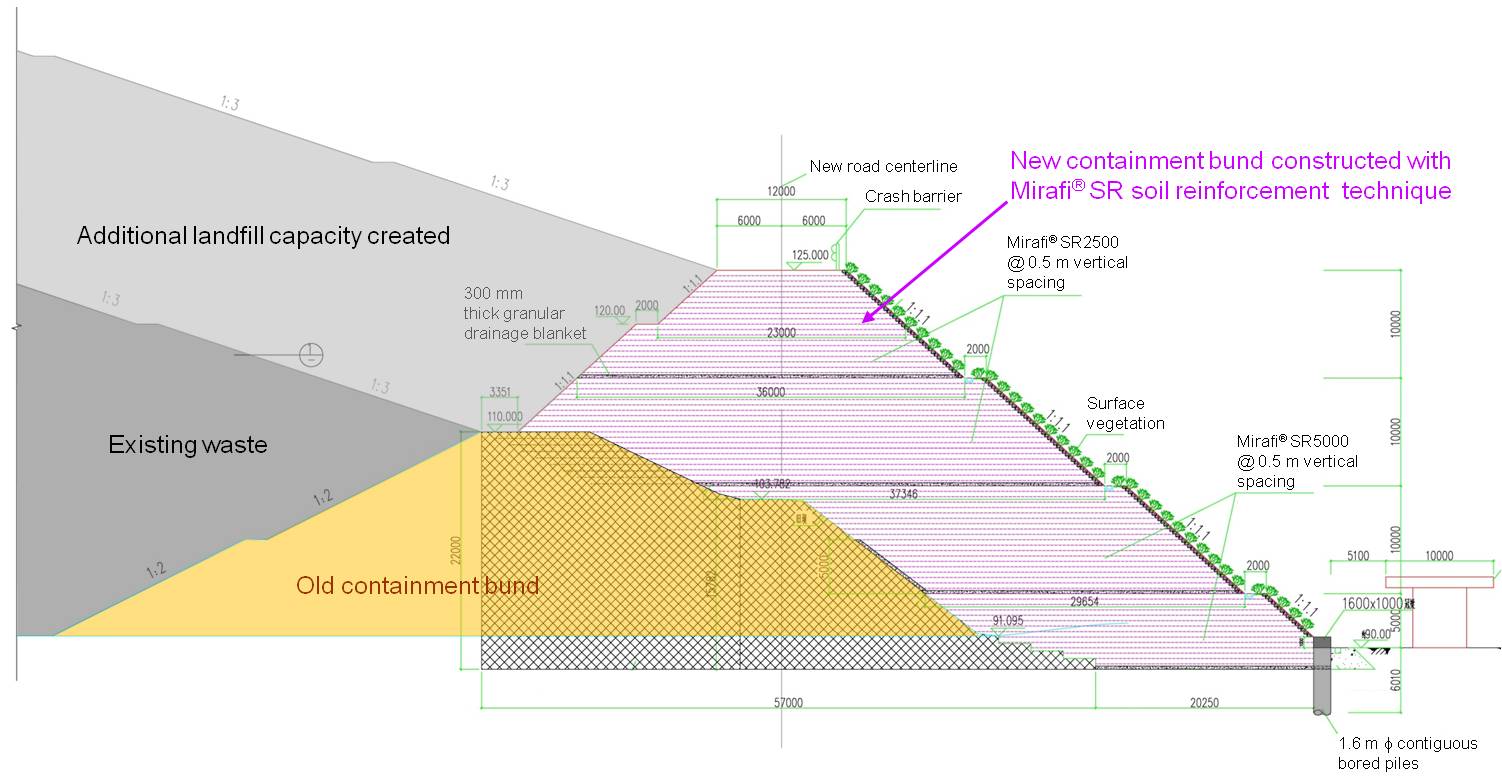

This project involved the capacity expansion of the existing Xinfeng municipal solid waste (MSW) landfill by raising the height of existing containment bund to handle the drastic increase of daily MSW generated in Guangzhou, China. The length of the containment bund = 300m, Total max. height = 37m including 2m which is embedded below ground level.

What was the purpose of this project? What did the client request?

With a population of about 14 million people, Guangzhou is one of China’s leading manufacturing and commercial centers and generates a significant amount of municipal solid waste (MSW). For many years, Guangzhou’s solid waste has mostly been sent to the Xinfeng MSW Landfill in Baiyun District of Guangzhou City. It is the second largest landfill in China in terms of capacity and daily MSW intake, second only to Laogang MSW Landfill in Shanghai. It covers an area of 917,000m2, out of which is 565,000m2 of landfill cell area with a landfill capacity of more than 26 million m3. The landfill was originally developed in 2003 with a design capacity of 19.3 million m3 and based on 3000 tonnes of MSW daily had a projected collection life of 20 years. By 2010, Guangzhou was producing 8000 tonnes of MSW daily, out of which 7000 tonnes were sent to Xinfeng Landfill. It was clear that Xinfeng Landfill was quickly running out of capacity by 2012. There was an urgent need to find a way to increase the capacity of Xinfeng Landfill, without which Xinfeng Landfill would have to stop accepting waste. This would have had drastic consequences for the city of Guangzhou as new landfill and incinerator projects are still at a planning stage. The idea of reinforced soil technology using Mirafi® SR reinforcement woven geotextile came into the picture and provided the most economical, and best technical solution to expand and maximize the height of the new containment bund. The new containment bund will contribute 7.5 million m3 of capacity increase.

What is unique or complex about the project?

This new containment bund is located between the existing leachate treatment plant and the existing low containment bund at the southern end of the landfill. Due to site constraints and in order to gain optimum landfill capacity increase, the sides of the new containment bund were designed to slope at an angle of about 45 degrees. A row of 1.6m diameter bored piles was designed to act as shear key at the toe of the new containment bund to provide adequate stability against global failure. The bored piles typically ranged from 18m to 21m in length. There are 3 intermediate berm setbacks of 2m each with the top containment bund of 12m wide for the access road. Wrapped around system with the soil bags are used at both ends to facilitate and form the slope geometry. The new containment bund is connected into the original containment bund using steel dowels. When completed, a layer of topsoil was placed over the external face and vegetated over.

What were the results of the project?

The client is extremely satisfied with the geosynthetics reinforced soil system. The construction of the new containment bund could be completed within the stipulated timeframe with the ease of installation and minimal heavy construction machineries were required on site. This was an important milestone given that the kind of challenges facing China in managing its solid wastes, including the significant investment necessary to manage the growing volumes of waste generated.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG