Company:

Canvas innovations

Project Details

Fabric 1

Soft Touch

Producer:

Marlen Textiles

Supplier:

Trivantage LLC

Design Name

Ken DeGroot

Design Company

Canvas Innovations

Fabrication Name

Mitch Lemmen, Chelsea Freers, Stacy Chandonnet, Ken DeGroot

Fabrication Company

Canvas Innovations

Installation Name

Mitch Lemmen, Ken DeGroot

Installation Company

Canvas Innovations

Please describe the project specifications

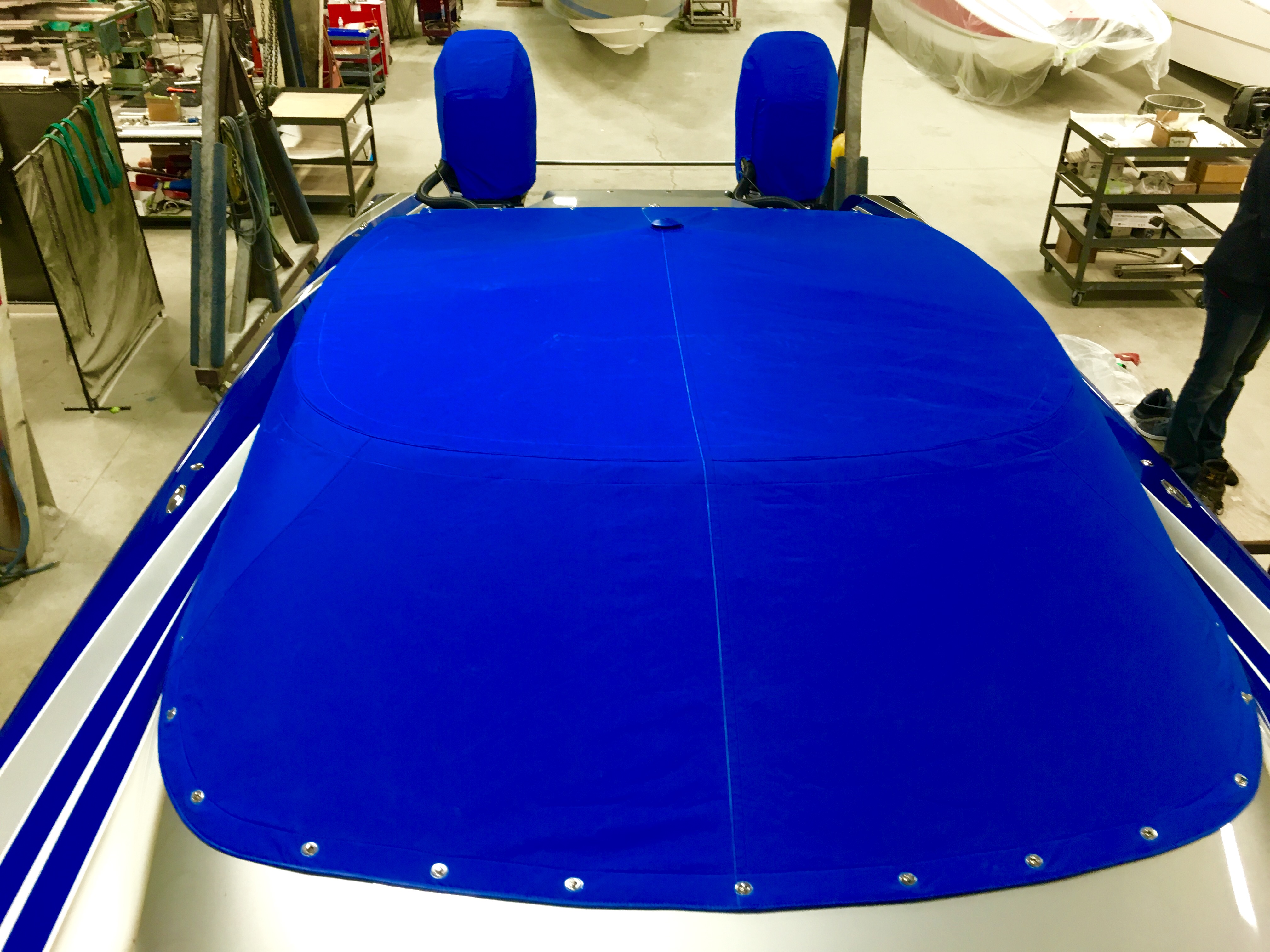

Our client wanted to protect his brand new boat both on and off the water, so we designed four separate covers to achieve this. The biggest one was the full cover that protects the boat all the way past the water line. For the times the boat is slipped, we made a easy on/off cockpit cover as well as two motor covers for the matching 400 Mercruiser Racing outboards.

What was the purpose of this project? What did the client request?

This boat travels across the country participating in poker runs, and because of that our client needed a good sturdy cover to protect it from stone chips and grime while in transit- plus they wanted some easy on/off covers to keep it in top condition while slipped.

With a boat traveling thousands of miles at highway speeds these covers required special care in patterning, proper material, and precise construction in order to hold up to the elements and protect the boat. The main objective was to make these covers easy to install. Our client did not want to struggle with covers after a long day of boating and racing.

What is unique or complex about the project?

This job required 75 yards of Soft Touch fabric in order to make all the covers!

The cockpit cover is a piece we make regularly for the boat manufacturer. It is designed to fit snugly and be gentle on the boat's finish. With common sense fasteners on the front and stern end, and snaps across the sides, the cover stays on tight when it is needed for short tows.

The 400 Mercury outboard covers were a little bit of a challenge. They are tailored to fit, yet easy to slip on. We used 1'' webbing inside the bottom hem across the bottom of the cover. We then used side release clips to attach it back to itself. These covers are usable both on and off the water.

The bulk of our time investment was in the full cover. We knew this cover would be a challenge to pattern and to sew, it was like a giant puzzle! The travel cover protects the entire boat, and these race boats are catamarans- which allowed us to bring the fabric all the way to the bottom and span the gap with tension straps. Trailer-able covers are complex by nature because they see the most wear and tear. Every piece of the full cover was patterned to the boat to make sure the fabric molded to the hull to provide complete coverage and defense against the elements.

What were the results of the project?

The covers were user friendly and fit like a glove. Our client and the boat builder were extremely satisfied with the projects. We ourselves are happy to have achieved the desired results, and are proud to showcase the finished product.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG