Company:

Napier Auto Upholstery

Project Details

Fabric 1

Vinyl

Producer:

Supplier:

N/A (Motor Trimmer from Auz moved back from NZ and we purchased bulk material from him as this was some we purchased)

Please describe the project specifications

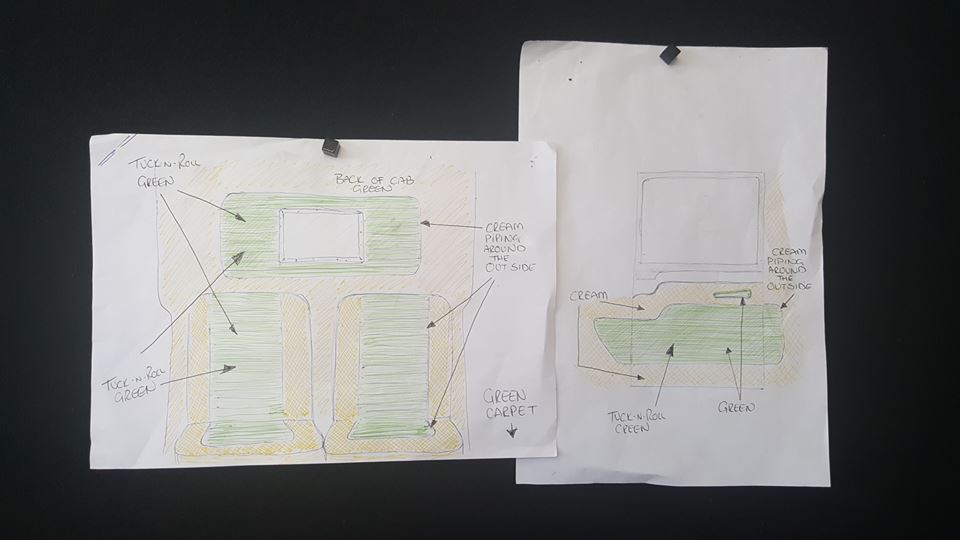

Our client was great to deal with as he had very firm ideas of what he wanted and had drawn up detailed plans with colours and style lines. The truck has an old exterior look and he wanted to keep the working truck look but with a wow factor interior along with the gold dash he had already fitted. The seats were frames that we had to build foam to create the seat shape. We also had to make new door panels and the back wall paneling. This project was interesting due to the fact the owner was able to help provide his thoughts/ideas when parts of his design were not able to be easily transferred from paper to the vehicle. He has a background in panel work and engineering so understood some of the processes involved. The panel around the rear window was made from sheet metal and bolted with set bolts to be held in place. I designed the panel and our client made it. The fabrics used were new old stock vinyls from a 1974 ford with perforated holes and off white vinyl.

What was the purpose of this project? What did the client request?

The client gave us a hand drawn design he had done and wanted us to replicate it in his car. He knew exactly what he wanted so made the communication about design seamless. The outside of the truck has the old working truck look but he wanted a wow factor interior to match his gold dashboard.

What is unique or complex about the project?

The pleats were drawn to run across the vehicle which made it more of a challenge. The panel around the back window was unique. This was designed by myself and made by our client. The complex part of this job was to get all the lines flowing on the door cards, seats and back window without it looking out of place. Fitting the seats in the vehicle was also a challenge as there was limited space and putting the back panel in meant we needed to cut out the panel for the seats to recline back further but then to cover the panel so the recess wasn't noticeable was complex also.

What were the results of the project?

The client was over the moon with the finished interior, especially the padded trim around the rear window as it was easy to draw but hard to produce.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG