Company:

Moss Inc. Chicago, IL

Project Details

Fabric 1

OTHER

Producer:

Fisher Textiles

Engineer Company 1

Moss

Design Company

Imagination The Americas

Fabrication Company

Moss

Graphics Company

Moss

Installation Company

Moss

Please describe the project specifications

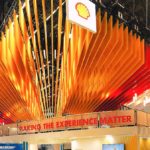

In both a brand and trade show debut, this exhibit stood out as an engaging, immersive experience designed to create awareness and affinity with an emotional connection. It featured a high-volume succession of rectangular tension fabric panels to create a visually stimulating shell for the exhibit. We fabricated 82 hanging panels, positioned both vertically and horizontally, with some coming in at more than 90 ft. long. The panels utilized 100 percent opaque printed BarrierTex fabric. We also provided multiple highly visible hanging lightboxes with perimeter LED lighting technology.

What was the purpose of this project? What did the client request?

As a new brand, Shell Polymers was bringing out its first ever trade show exhibit, an 80x50 footprint with a double-decker design. We helped transform the space into a high-impact destination, which ultimately totaled 5,700 sq. ft. over two stories.

Shell Polymers launched its campaign of “Making the Experience Matter” at NPE, an every-3-years show, with a customer-centric focus and initiatives. It also unveiled details of its ambitious 386-acre U.S. production facility under construction near Pittsburgh, Penn. that will process natural gas.

What is unique or complex about the project?

The project was a deep collaboration between our client Imagination The Americas and our Solutions Development, Customer Success and Installation Supervision teams.

Through research and discussion with Imagination, we presented a fabrication solution that would maintain design intent and also meet critical show site requirements and installation timelines. Our powdercoated frame solution gave a nod to the desired look and feel of polymer while proving easier to execute on site, compared to timelines and resources that would be needed for a heavy volume of rigid goods.

In order to greenlight the project, we provided exact fabrication processes, packaging & shipping specifications, samples, and critical project milestones to galvanize the concept and confidence.

Once fabrication commenced, weekly progress meetings ensured key information was being shared all the way through the exhibit’s spectacular finished installation.

What were the results of the project?

Between the 2,100+ exhibitors and 55,000+ attendees, Shell Polymers’ message at NPE was heard loud and clear. A Shell Polymers spokesman remarked “We were very pleased with our reception at NPE and the feedback we received on our booth was very positive.”

Industry media observers said the “booth impressed in size, in footprint and height in addition to its prominent location at the entrance.”

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG