Company:

ECO LIGHT WEIGHT STRUCTURES & ARCHITECTURE

Project Details

Fabric 1

précontraint Serge Ferrari 902

Producer:

Ferrari SA

Engineer Name 1

Samuel Alejandro Carrillo Garcia & Javier Ivan Roomero Gonzales

Engineer Company 1

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Design Name

Samuel Alejandro Carrillo Garcia

Design Company

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Architect Name

Jose Luis Soza Valdez

Architect Company

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Fabrication Name

Cristian Eduardo Carrillo Garcia

Fabrication Company

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Graphics Name

Jose Luis Soza Valdez

Graphics Company

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Project Manager Name

Samuel Alejandro Carrillo Garcia & Hector Isaac Acosta Torres

Project Manager Company

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Installation Name

Hector Isaac Acosta Torres & Ricardo Cervantes

Installation Company

ECO LIGHTWEIGHT STRUCTURES & ARCHITECTURE

Please describe the project specifications

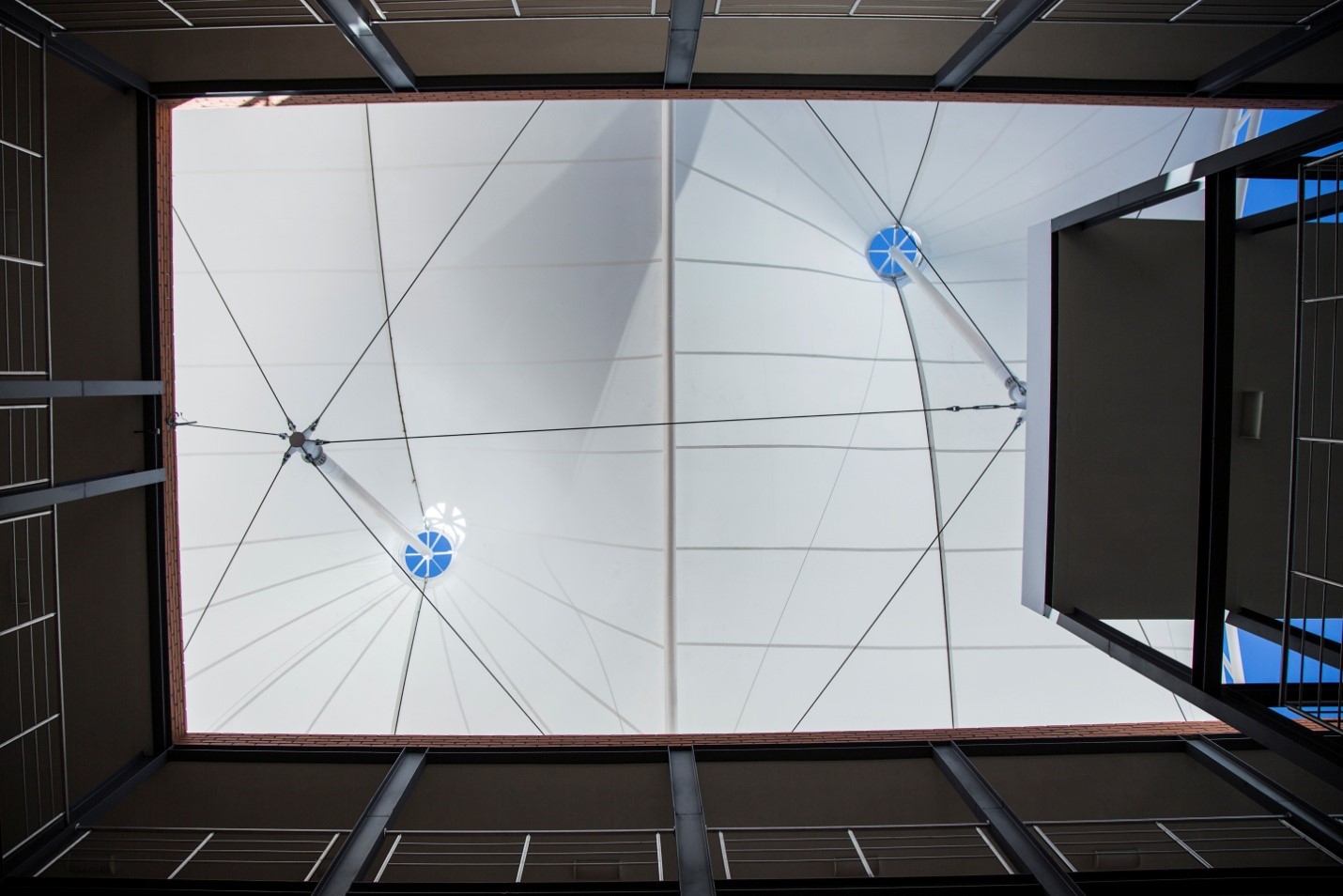

Our project called "suspended conoids in building Durango Mexico", is a project that has a significant impact on our final client, due to the dynamism achieved, this project was calculated for 150 km / hr, has an area of 432 square meters in plan with measures of 18 x 24, resulting approximately 550 square meters of membrane in development,, for the project were used around 8000 kilograms which is quite light for a tensile structure, used precontraint Serge Ferrari 902 white membrane, giving natural light during the day, apart from the dynamism of the form in conjunction with the inclined masts and the perimeter of the irregular rigid structure in the form of waves, this concept was based on the mountains that are around of this building in the city of Durango Mexico. The entire tensile structure system was anchored to existing concrete columns of the building to be covered for students, water and sun.

What was the purpose of this project? What did the client request?

The purpose of this tensile structure was mainly to cover sun and water for a common area for university students, the client requested a solution of quick execution, and that it was an icon to identify the university where we installed the project, as well as the client needed natural light for the building so we installed Precontraint Serge Ferrari 902, because it was light and translucent, so the client did not want us to make anchors in the slab of the building, so the steel structure is anchored by steel columns directly to concrete columns of the same building, the rigidity of the conoids was obtained by cables and masts with a system that allows to give height to obtain a greater tension of the fabric, the whole tension system is supported to the perimetral structure of structural steel.

What is unique or complex about the project?

This project is unique for its form and concept, since we rely on the form of mountains that are located around the university, in this way we draw the visual part of the project being an ICON for the building within the University, the most important challenges complicated were the height of the building since it was 20 meters high, so to assemble the structure, cables, and fabrics, it was necessary a crane of 80 tons, and not by the weight of the roof but by the distance from floor to the maximum point of the height of the tensile structure, another important challenge was that there was not enough space to prepare the fabrics nor the steel, so the steel was mostly manufactured in the workshop and the fabric also, so it was all ready to install and on site was adjusted to be finally perfect, this required a lot of coordination with our team of welders, painters, installers, engineers, architects, and all of the above with a major challenge, was the time of execution for the opening of this building, however everything was administered perfectly, and times went ahead.

What were the results of the project?

The final result was sensational, it turned out to be an ICON for the University building, since the client loved it, even to date we were asked for new proposals for other projects within the same university.

the result of the project was the expected, light, impactful, dynamic, translucent and with all this finally a work of unique architecture for the world of the Tensile Structures with architectural membranes combining cutting edge engineering and avant-garde architectural designs.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG