Company:

Disaster Management Group, LLC

Project Details

Fabric 1

Polyvinyl Chloride (PVC) Laminated Fabric

Producer:

Primary Use:

Main Fabric

Engineer Name 1

Neal Balasny

Engineer Company 1

NB GLOBAL SOLUTIONS LLC

Design Name

Nate Albers

Design Company

Disaster Management Group, LLC

Architect Name

Dan Ionescu

Architect Company

Dan Ionescu Architects

Fabrication Name

Zach Downey

Fabrication Company

Elite Glass

Subcontractor Name

Dean Byrd; Dennis Reid

Subcontractor Company

GenServ

Graphics Name

Mike McLaney

Graphics Company

Event CAD Plans

Project Manager Name

Tom Rubio; Derek Spence

Project Manager Company

Disaster Management Group

Installation Name

Various

Installation Company

Disaster Management Group; GenServ

Please describe the project specifications

FEMA requested 30 Mobile Vaccine Units (MVUs) able to reach people in urban and rural areas as well as those who are unable to leave their place of residence to receive a COVID-19 vaccine. The turnkey MVUs can administer 500 to 1,000 vaccines per day and are ideal for reaching any rural area, community, park, or housing facility in the United States.

Each MVU contains an ultra-low (Pfizer), a low temperature (Moderna) freezer, and a medical refrigerator (Johnson and Johnson) to keep vaccine vials at their proper temperature and in accordance with manufacturer’s specifications.

The MVUs contain tracking and logging technology, including dashboard reporting services and mobile monitoring of all onboard systems. The MVUapp, a mobile app developed by DMG, is used to perform morning, midday and evening inspections, track medical waste drop-offs and water services, and a checklist to perform a site breakdown and demobilization. DMG made onboard WIFI available to the clinical staff for vaccination scheduling and to report the number of vaccines loaded, administered, and returned.

Mobile Vaccination Unit Specifications:

- Each MVU includes a vaccination trailer (size= 8' x 32'; GVWR = 18,000 pounds) with a heavy-duty tongue that supports a waste tank and HVAC. An extension on the back of the trailer supports an onboard diesel generator.

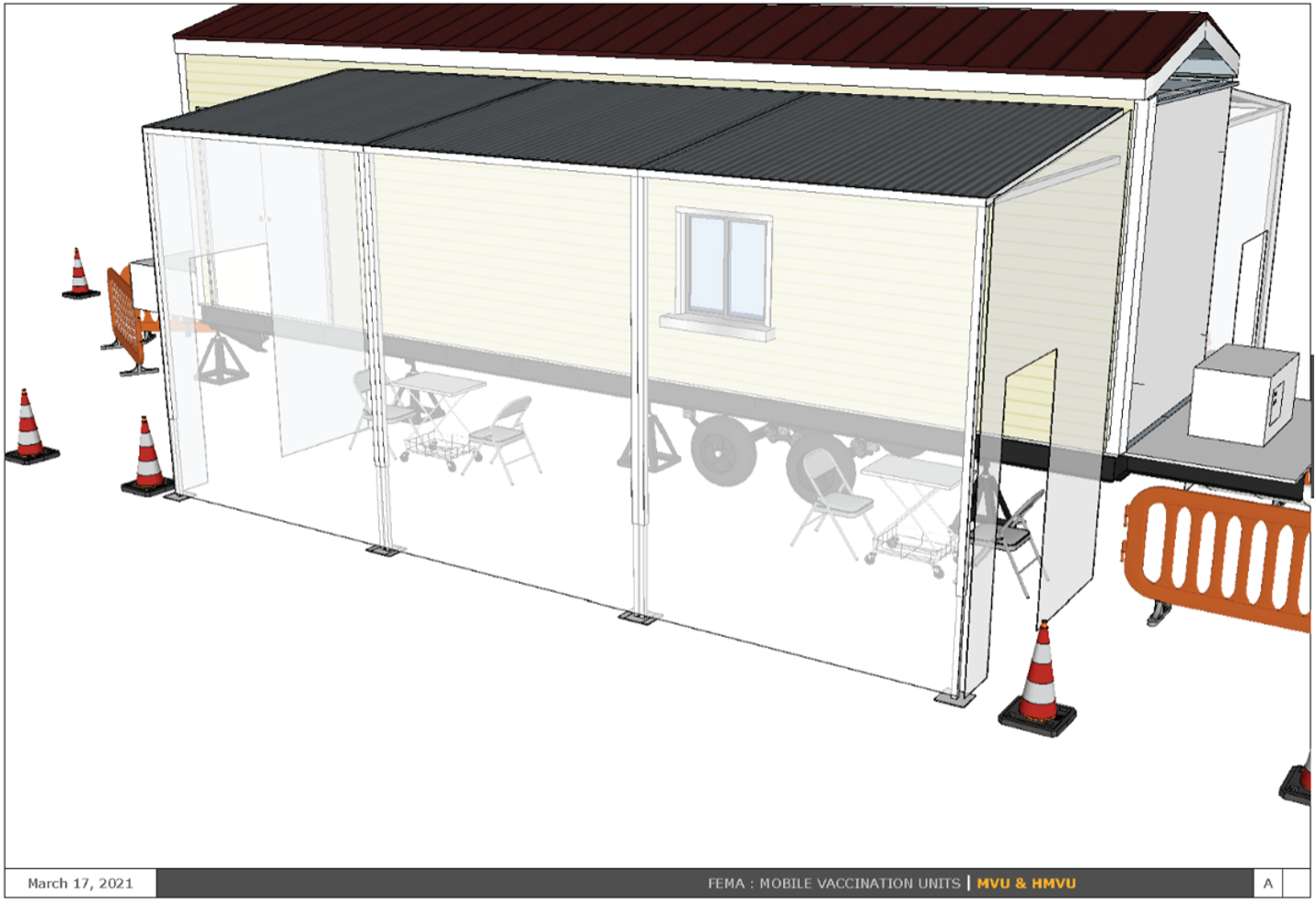

- Vaccine Administration: We MVU features (2) 8’ x 24’ Retractable Awnings with one on either side of the trailer. Each awning features a hard vinyl roof system, vinyl sides with zipper doors, AC/heat ducts, external outlets, LED lighting, etc. One side of the enclosed awning area is used for vaccine administration and the other side is used for observation. The functionality of the covered awning areas enables the medical staff to have a dedicated internal clinical area while working with patients in a separate area.

- There are pass through windows on both sides of the trailer that can be used for distributing vaccines. The interior of the unit features the freezers and refrigerator mentioned above, a counter for vaccination prep, and storage areas. The trailer also has a don/doff area. Tables and chairs are included for exterior use.

- Staff/Operations Support: The Vaccination trailer features an administration desk and chair for reporting, storage space, onboard bathroom, staff lockers, and PPE storage. Additional staff support includes a mini-refrigerator, counter, and coffee maker for staff use. The MVU also has a full restroom onboard, supporting routine hand washing necessary when administering vaccines.

- Power Generators and Freezers: The MVUs are equipped with diesel generators, UPS battery backup for the onboard vaccination freezers and fridge, and a secondary generator on the support trailer. This redundancy ensures 24/7 operations and continuous power generation to keep the vaccines at the necessary temperature. The two onboard freezers are configured for the most ideal temperature for vaccine storage (one ultra-low temp freezer (-50°C to -86°C, -58°F to -122°F) and one low temp freezer (-10° to -25°C, +14° to -13°F)). The total storage capacity for both freezers makes up 3,600 vials or 25-30k shots.

- Batteries: Power protection and redundancy is provided with an HD alternator, 4 deep cell batteries (3-day holding period off the batteries alone), inverter, comms, telematics. Both carry medical sharps and waste containers we remove/dispose of.

What is unique or complex about the project?

We have been providing disaster and relief support to FEMA and other government agencies since 2006. Given our experience to rapidly deploy temporary (Tent) structures with a very short notice to proceed, FEMA chose us for this very unique project.

This project was special because we knew we were going to be helping 10s of thousands of citizens who may have difficulty receiving a COVID-19 vaccine. The MVUs have roughly 4 times the capacity of a van but are nimble enough to move from place to place. The MVUs were deployed nationwide from metro areas like NYC to very remote areas in the southwest US.

Our history in the tent business dates to the late 90’s. Given that history, we needed a fabric solution that provided versatility and durability. We chose a polyvinyl chloride (PVC) laminated fabric. PVC is the third most used plastic and highly suitable for outdoor uses like the demands required by our mobile vaccine units. The PVC material on each MVU is installed and used for several days and then deinstalled, folded and stowed away to travel to the next destination. An MVU will make as many of twenty stops per month.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG