Company:

Signature Structures

Project Details

Fabric 1

Ferrari 942

Producer/Manufacturer:

Serge Ferrari North America Inc.

Primary Use:

Main Fabric

Engineer Name 1

Dirk Cos

Engineer Company 1

Lightweight Design

Design Name

Dirk Cos

Design Company

Lightweight Design

Architect Name

N/A

Architect Company

N/A

Fabrication Name

Signature Structures

Fabrication Company

Signature Structures

Subcontractor Name

N/A

Subcontractor Company

N/A

Project Manager Name

Curtis Mita

Project Manager Company

Signature Structures

Installation Name

Signature Structures

Installation Company

Signature Structures

Please describe the project specifications

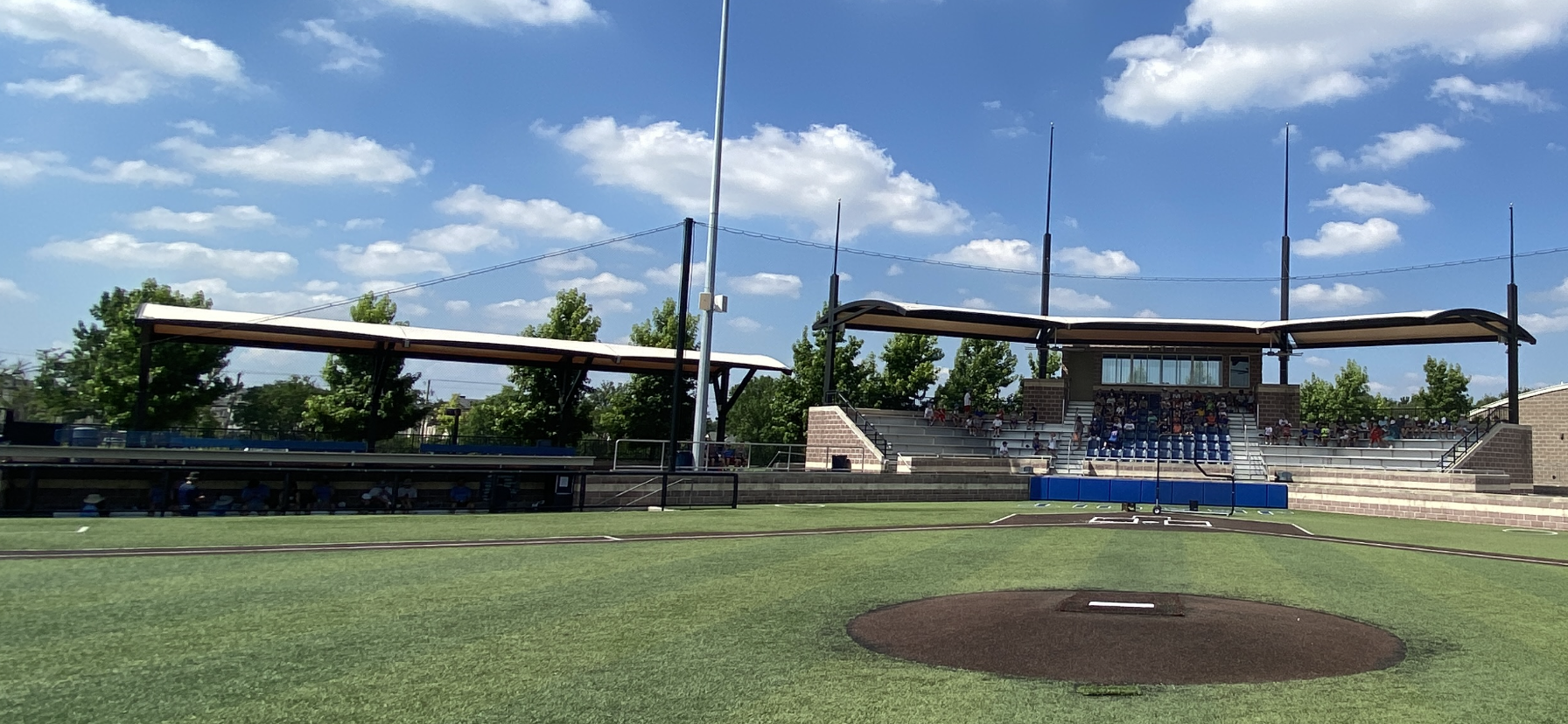

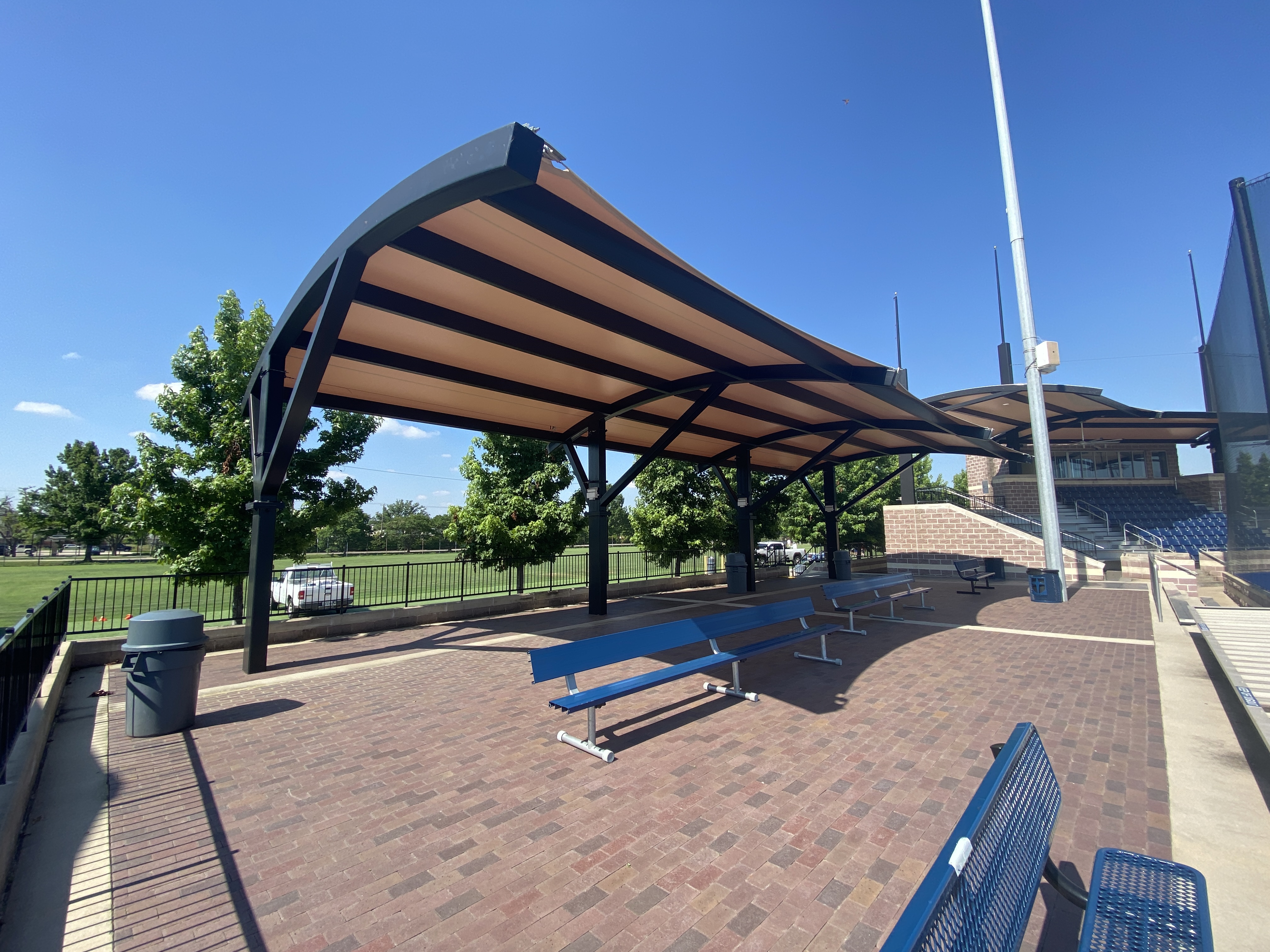

Jesuit Dallas Preparatory School had a series of sunshade canopies at their athletic facility which were skinned in a lightweight mesh fabric which was not waterproof. The canopies were damaged in a storm and the school wanted to take the opportunity to replace them with a heavier duty, architectural fabric.

Once our company began to design the replacement membrane solution, it was clear the the original design of attaching the membrane to the frames using cables in pockets strung through eye holes welded to the frames would not be adequate to securely attach the new, heavier architectural membrane to the frames. Thus, we designed, engineered and installed a completely new system including keder track attached to the frame and newly designed membrane plates.

We designed, engineered, manufactured and installed the complete new membrane system.

What is unique or complex about the project?

Client needed a company that specialized in retrofitting new systems to existing framework. Our company specializes in designing, engineering, manufacturing and installing new membrane systems on fabric structures of all types, regardless of original manufacturer.

This project was different in several ways. Our company typically looks to reverse engineer the current system to install new membrane re-using as much of the original design as possible to minimize costs to the client. However, in this case, the structure was designed to support what was little more that a "shade cloth" the was water permeable and not engineered to handle true loads. It was clear early on that we would need to design a completely new attachment and tensioning system for the structure in order to utilize a heavier duty architectural fabric.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG