Company:

MarineRennavators LLC

Project Details

Fabric 1

Silvertex Plata

Producer/Manufacturer:

Keyston Bros.

Primary Use:

Main Fabric

Fabric 2

Silvertex Ice

Producer/Manufacturer:

Keyston Bros.

Primary Use:

Secondary Fabric

Design Name

Kelsey Renna

Design Company

MarineRennavators LLC

Fabrication Name

kelsey Renna

Fabrication Company

MarineRennavators LLC

Installation Name

Tov Renna

Installation Company

MarineRennavators LLC

Please describe the project specifications

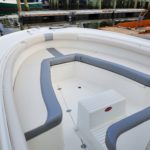

This project involved the complete remake of all the exterior cushions and bolsters on a vessel recently purchased by a new owner. The existing upholstery consisted of a monotone white and off white vinyl with faux knee and neck rolls. The foam base of the cushions had also deteriorated to the point where it was compressed and misshapen and not salvageable to properly fill out new covers. The customer requested an upgraded vinyl that was still easily cleanable along with a silver or grey colored stripe/ roll to give a bit more pop to the boat. We suggested Silvertex for the base vinyl because of its fabric like texture and still being a vinyl is relatively easy to clean and maintain. With the base fabric and secondary color confirmed we moved ahead to the next issue, foam. The original upholstery had been manufactured with generic UC foam, which holds moisture and mildew and is not really designed for exterior use. We opted for reticulated EZ dry foam, which the customer agreed, and built the new seats with a layered composite of dense foam on the bottoms of the cushions and a soft layer on top to give the cushions a soft feel but a firm core so you don't bottom out.

With the foundation of the cushions agreed upon we moved on to the visual design. The existing cushions had been made with straight simple faux rolls across the forward edges of the cushions and backrest's. We decided to add a bit more character and created curved rolls with actual upraised knee and neck rolls ( 5" knee rolls with a 3" seat) in the secondary color for better support and flowing lines.

All the upholstery received the same treatment of new foam and design, while reusing the base plastic where applicable. The forward console backrest was the only cushion that required a new piece of Aquaplas PVC cut to allow it to be made with the same modus apperandi as the rest.

The finished product gave the customer the look they where hoping for, a softer more fabric feel, while still being a fairly forgivable vinyl with a highlighting color to break up the old monotone look, along with new foam for better comfort and support.

What is unique or complex about the project?

We picked this project to enter because as a new startup canvas shop in our area it allowed us to showcase our abilities to not only manufacture canvas covers and goods but upholstery as well, which most customers find surprising that we are able to both.

This particular customer had their boat brought to us from south Florida when they weren't able to get the work completed down there. They were given our contact information from the local boatyard, and proceeded with the work even though we had only done small cushion repairs or replacements at that point. This was our first complete cushion remake in the infancy of our new company. It allowed us to showcase our abilities and establish a relationship with the local shipyard and boating community, a much needed boost as we had opened shop at the beginning of the pandemic and had a very difficult first year with limited contact and access to everything in the marine market.

It isn't the largest or most outrageous project, but it was very important to the future of our small company.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG