Company:

W A Coppins Ltd Motueka,

Project Details

Fabric 1

High Tenacity Nylon (special design for highest strength - but light weight

Producer:

Supplier:

W Wiggins Ltd

Fabric 2

Dyneema Rope 9specially designed -20mm 54.7 ton breakload, 5mm -4.8 ton break load

Producer:

Hampijdan NZ Ltd

Supplier:

Hampijdan NZ Ltd

Fabric 3

Spectra Webbing 50mm

Producer:

Webbings and Tape, NZ

Supplier:

Webbings and Tape, NZ

Fabric 4

PTFE

Producer:

W Wiggins Ltd

Supplier:

W Wiggins Ltd

Fabric 5

PVC Coated Polyester

Producer:

Gale Pacific NZ Ltd

Supplier:

Gale Pacific NZ Ltd

Design Name

Bill Copppins

Design Company

Coppins Sea Anchors Ltd

Fabrication Name

Ryan Coppins

Fabrication Company

Coppins Sea Anchors Ltd

Project Manager Name

Bill Coppins

Project Manager Company

Coppins Sea Anchors Ltd

Installation Name

Ryan Coppins, Bill Coppins

Installation Company

Coppins Sea Anchors Ltd

Please describe the project specifications

There has been rapid growth in the number of super-yachts globally, and increasing demand for ways to protect these in the event of extreme weather, equipment failure or other emergencies at sea. The demand is driven by the growth and increasing value of the fleet, by insurance and other requirements, by growing recognition of risks to crews and vessels and of potential salvage costs, and by the risks and costs of polluting coastlines or the marine environment. In the event of an emergency at sea, time is not just money; it might mean loss of lives or vessels or other damage as well.

Super-yachts can vary in size and there is no precise definition; with regard to this project, this is considered to be a vessel having a length from about 30metres to 120metres (100 to about 400 feet).

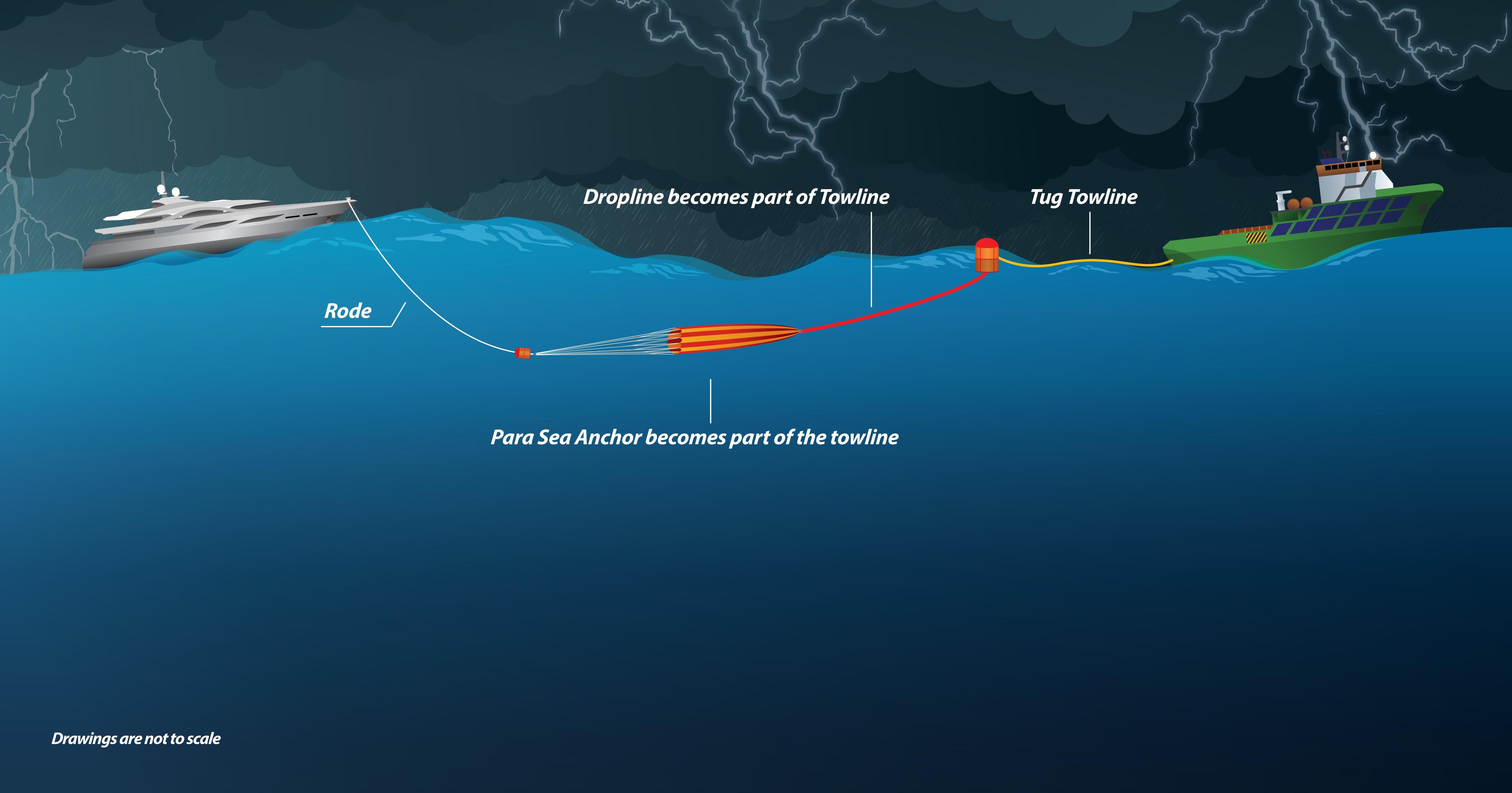

A para sea anchor (PSA) is essentially an underwater parachute, and can play a vital role should a super-yacht face an emergency at sea: It swings the vessel round to face into the weather, stabilizing it and reducing the risk of capsize, and slows its rate of drift. This can allow crucial extra time for help to arrive or for repairs to be made.

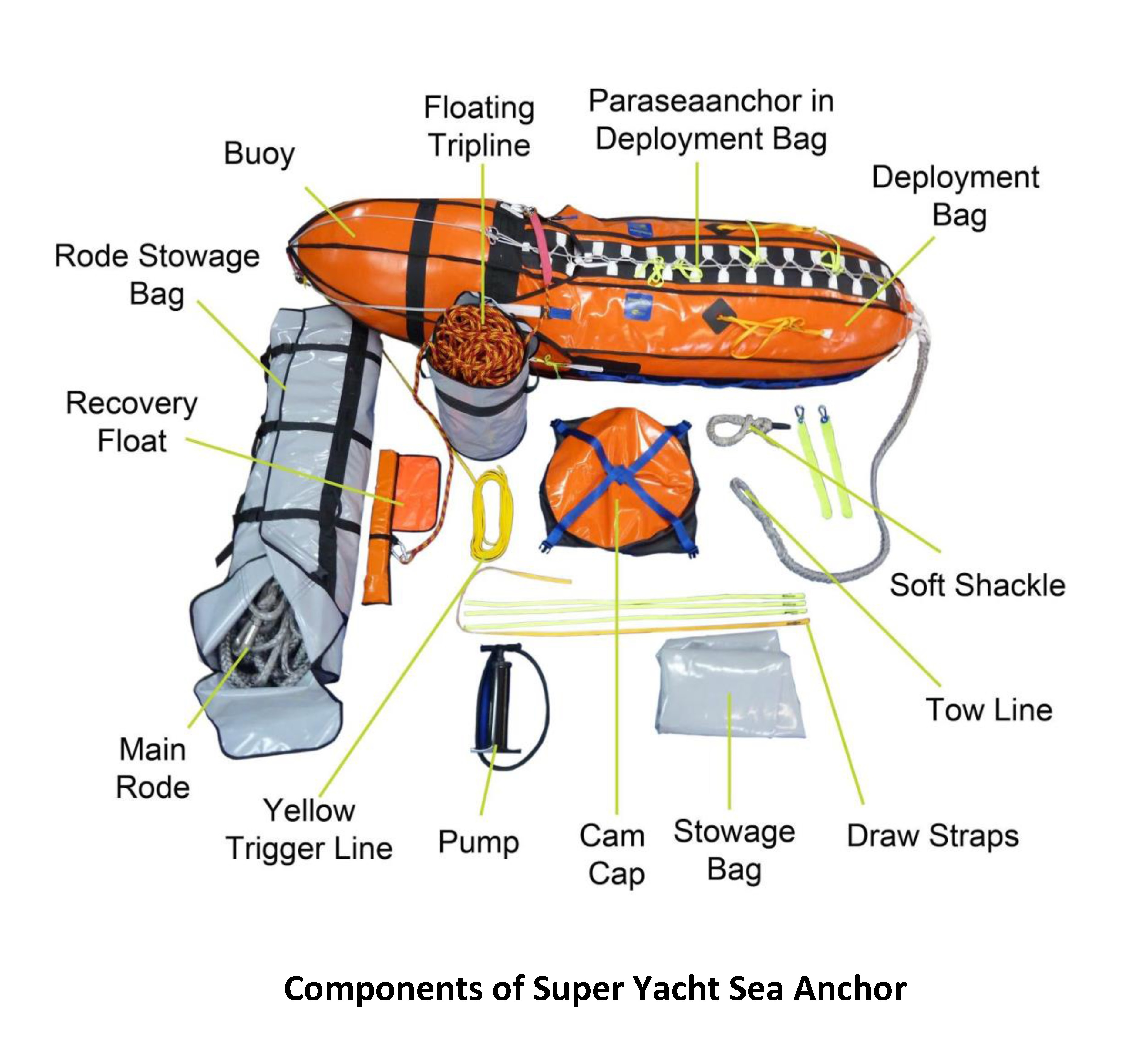

In this sea anchor there are five features that make it stand apart, including three features never seen before. First, the strength and lightness of all our anchors are unmatched, anywhere in the world. Second, our clear focus on minimising environmental impacts is built into every one of our products. But the features of this sea anchor that are totally new and innovative are as follows. Its fully integrated towline allows quicker, fail-safe rescues from a much greater distance than previously possible, reducing risks to lives and vessels. Next, a new release mechanism enables instant deployment of the anchor, as soon as it is clear of the super-yacht. And finally, an innovative compression system allows the product to be packed easily by one person, saving time and space; its compact size and light weight means this life-saving product is more likely to be carried on a yacht, where space is always limited.

What was the purpose of this project? What did the client request?

Our client, a distributor in Nice, France which sells yacht supplies globally, had recognised a need for a PSA with an effective rescue system, and approached us for a solution and to design one. A $US39 million mega-yacht (MY Yogi), thought to be almost unsinkable, had recently sunk in the Aegean. The client is based on the shores of the Mediterranean, where sea conditions are frequently quite benign and yachts are often less robust than in other oceans. But dangerous storms can arise quickly in the Mediterranean (we experienced 8metre breaking waves – 26 feet - while trialling there) and super-yachts passing through this area might sometimes be required to cross the Atlantic, Pacific or other oceans.

The client requested a product designed to withstand storm conditions, but with an easy-to-deploy rescue system, for sale to owners of ocean-going yachts and super-yachts. An effective PSA should prevent loss of lives and damage to yachts in the event of a gear failure, extreme weather event or other mishap, and should help to avoid pollution and damage to other property. And it should provide for easy rescue by tug or coast guard, as required under an international convention for ocean-going commercial yachts to have effective, well-documented emergency procedures. A quicker, safer rescue system would also reduce or avoid repair and salvage costs, and insurance company claims. Our proposal, with a fully-integrated rescue system, was seen as a way of meeting and going beyond such requirements.

What is unique or complex about the project?

Our company has always aimed to make the world’s best sea anchors. To maintain leadership we are committed to ongoing research, development and improvement. This project incorporates the following:

i. Strength, Quality and Design

We continue to design and search worldwide for better, lighter, stronger materials and manufacturers to produce them. Our designs and quality of workmanship continue to innovate and evolve, optimising the strength and qualities of the selected materials. The materials chosen are shown in Section 1, above. We take pride in the fact that over five decades our sea anchors have never failed or blown out, except under testing where they are often deliberately stressed to breaking point. This product is available in a range of eight sizes, depending on the size of the super-yacht.

ii. Environmental Performance

Our company puts a very high value on the product’s environmental benefits, including avoidance of pollution and waste. A super-yacht may carry several thousand litres of fuel; along with other potentially tragic outcomes, loss or damage to a vessel could mean spillage of fuels and other contaminants, polluting seas and coastlines. Also, super-yachts are commonly scrapped after being damaged in collisions; a speedy rescue will avoid an accident and therefore extend the vessel’s life. And the sea anchor itself is designed for a long life, being easily recovered and repacked after use, allowing multiple redeployments.

The same commitment to environmental protection is applied to the manufacturing process; testing of sea anchors is often carried out in powerful tidal rips rather than purpose-built tanks, and our designs minimise the waste of materials. Our firm is a pro bono contributor to an international project developing techniques to rid the seas of plastic waste.

iii. Integrated Rescue Towline

We were determined to enable quicker, safer rescues. The key was an integrated pickup towline, 275 yards (250metres) long in total, with the specially-strengthened sea anchor itself forming part of the towline. The recovery line had to be kept easily visible and in a straight line, floating on the surface, for easy location and pickup with a grappling hook from a rescue vessel. This means that the rescue vessel only needs to get to about 220 yards (200metres) from the stricken vessel, rather than within about 33 yards (10metres) with existing rescue methods, that there is no need to get the anchor out of the way, and that the recovery line is already firmly connected to the super-yacht. The result is to speed up the rescue time, to ensure success on the first rescue attempt, and to avoid injury, death or damage to the yacht.

iv. Controlled Deployment System

Also a sure-fire deployment system was needed: the product had to be ready to launch straight into the sea, with deployment able to be triggered as soon as the unit is completely clear of the stricken vessel. This trigger comprises a release cord running through the core of a web attached to a deployment bag; the cord is pulled to open specially-designed snap shackles, to release the sea anchor. This device increases deployment speed and control, vital in extreme conditions.

v. Assisted Packing System

Further to the above, the product includes a new and unique system for packing and compressing the unit, either before sailing or after deployment and recovery at sea. This can be operated by one person alone with no extra equipment. This means that the product requires less space and can be easily stowed, so is more likely to be carried where space is limited.

The system involves initially packing the sea anchor loosely into the deployment bag, with the half-inflated buoy strapped into the top of the bag. The buoy is then inflated to compress the unit, achieving a degree and evenness of compression of the fabric that would not be possible even with a hydraulic press. (It would be impractical anyway to carry the bulky framework needed for such a press on a yacht.) Straps on the unit are then tightened and the buoy can be deflated. This new development will certainly have further applications in other products, for compressing fabrics or other materials.

None of these last three features had been incorporated in any super-yacht sea anchor previously manufactured.

What were the results of the project?

The major benefits are firstly, quick and fail-safe deployment, rapidly stabilising a disabled yacht, turning its bow into the weather, slowing drift and preventing a collision with rocks or other vessels; in short, these are the results one would hope for from an effective PSA in an emergency.

The second major advantage is the speed, safety and avoidance of loss available with a system that a rescue vessel can connect to at some distance from the stricken yacht, allowing it to be towed to calmer waters or a safe harbour. Hitherto the common method of securing a disabled vessel involved shooting ropes from a gun (which, in most cases would not be available) on the rescue vessel at close range, or getting close enough to throw them, and hoping these could be attached to suitable points on the yacht and to the rescue vessel’s towing system. There is a significant risk of failure with this, and of damage to the yacht by the steel cables commonly used by rescue vessels. The new product allows the complete system to be set up on the yacht in advance, for a quicker, safer rescue.

Further, as well as protection from disaster, the client promotes our product as the perfect defence against environmental law suites and clean-up liabilities following an incident at sea.

Finally, the lighter and stronger materials used enabled us to achieve this agent’s weight-reduction targets.

The client has expressed strong satisfaction with this product and its fully-integrated emergency towline, and has signed a distribution agreement. They have appointed a marketing contractor for the product, and have a substantial budget for its promotion in the super-yacht world, with the model supplied being used as its flagship product. Ongoing sales are assured.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG