Company:

TRI Environmental Inc. Austin, TX

Project Details

Fabric 1

Geomembrane

Producer:

OTHER

Supplier:

OTHER

Engineer Name 1

Jason Ross

Engineer Company 1

S&ME

Fabrication Name

GSE Environmental

Subcontractor Name

TRI Environmental

Installation Name

American Environmental Group

Please describe the project specifications

This project is a coal ash landfill. The liner system components were manufactured by GSE Environmental and included, from top to bottom: 24” protective cover, 32 oz. nonwoven geotextile, 60 mil textured HDPE geomembrane, geosynthetic clay liner.

What was the purpose of this project? What did the client request?

Due to the Dan River failure and the North Carolina Coal Ash Management Act, Duke Energy has initiated new containment goals for the construction projects on already impacted land. The client approached GSE with the intent to achieve a leak-free containment system. GSE recommended a geomembrane and underlying GCL, in tandem with a soil-covered electrical leak location survey.

What is unique or complex about the project?

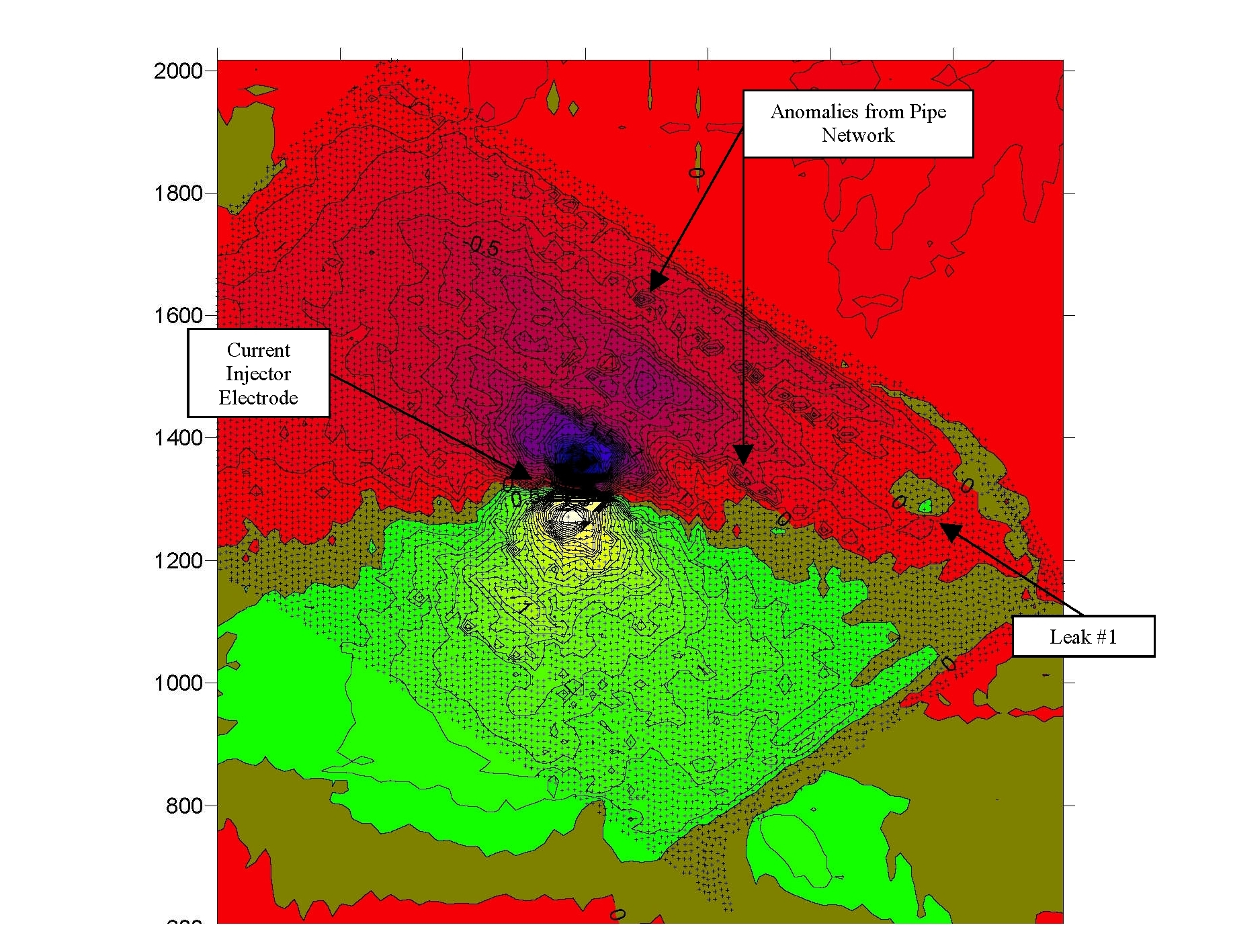

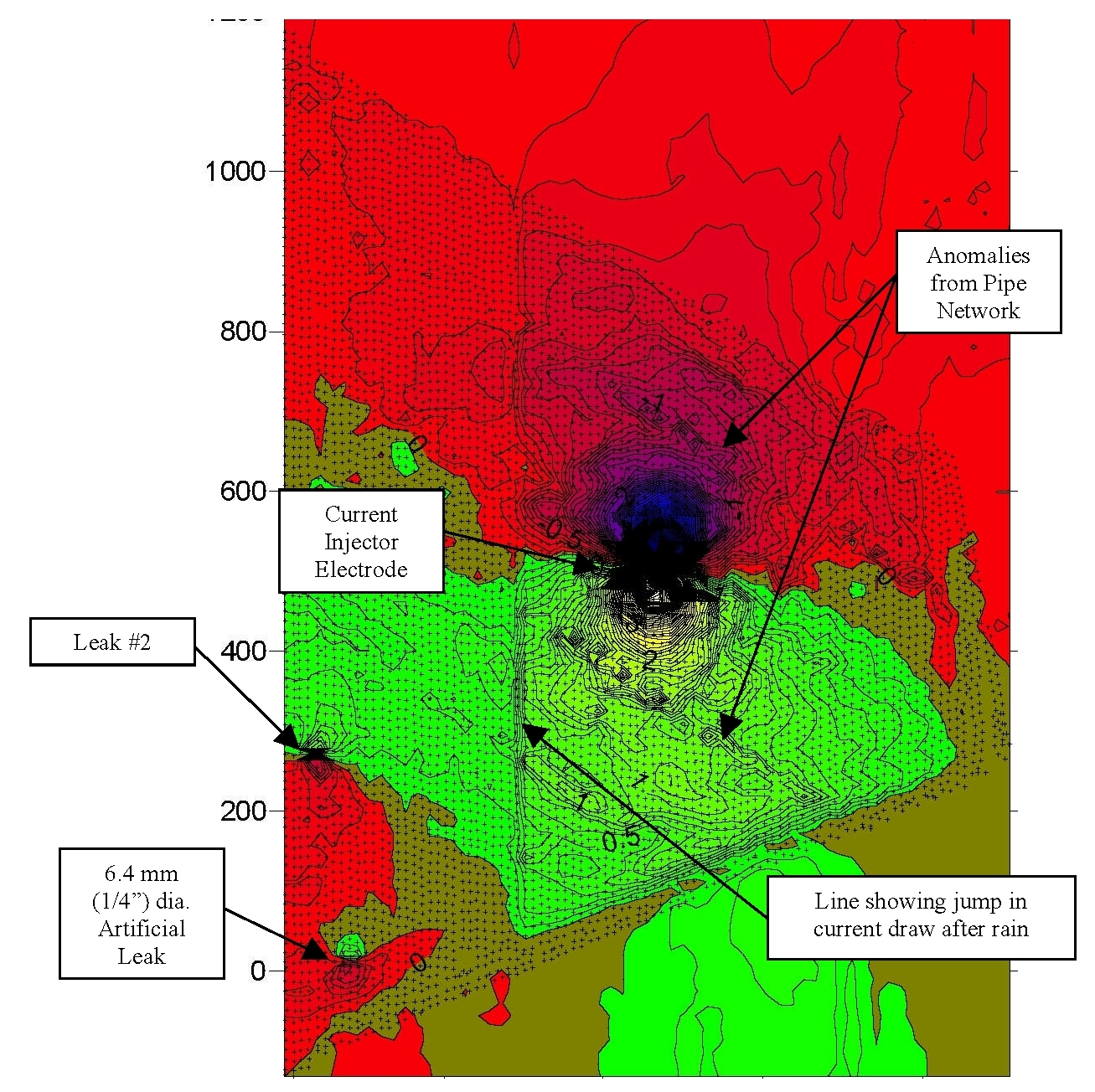

This was Duke Energy’s first project using electrical leak location technologies. Due to varying soil types and chemistries, it was unknown how well the survey would perform on the site-specific cover soils. The site was fairly large and due to the nature of having to take voltage measurements systematically every ten feet in a grid pattern, few companies have the capabilities of being able to rapidly and effectively survey a site of this scale. TRI Environmental surveyed the site in four working days and dug up the two located holes on the fifth working day.

What were the results of the project?

The complete voltage mapping of the site located precisely and with confidence the holes present in the lining system. The holes were subsequently excavated, repaired and resurveyed, assuring all parties that the lining system is now leak-free. Due to the voltage mapping, the site engineer and owner now have an invaluable quality control document, which shows that an electrical leak location survey was performed thoroughly and correctly. The owner intends on employing this technology on all similar construction projects in the future.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG