Company:

Canvas Specialty Los Angeles, CA

Project Details

Fabric 1

Spandex

Producer:

OTHER

Supplier:

OTHER

Engineer Name 1

Gregory Naiman

Engineer Company 1

Canvas Specialty, Inc.

Design Name

Gregory Naiman

Design Company

Canvas Specialty, Inc.

Architect Name

Brian DiMaggio

Architect Company

JFAK Architects

Fabrication Company

Canvas Specialty, Inc.

Project Manager Name

Gregory Naiman

Project Manager Company

Canvas Specialty, Inc.

Installation Name

USS Cal Builders

Installation Company

USS Cal Builders

Please describe the project specifications

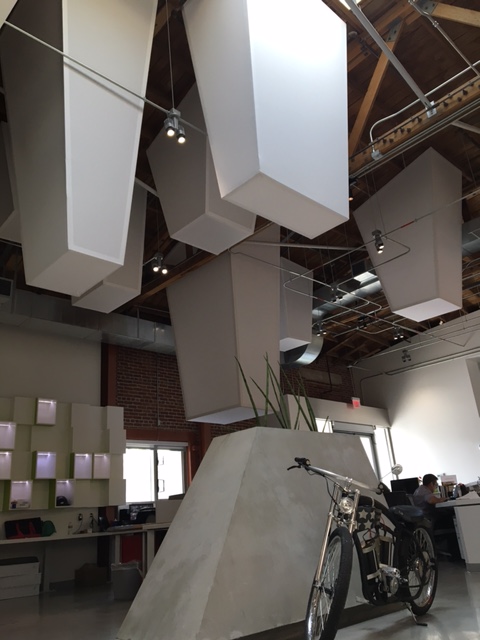

Our Company designed and manufactured fabric lanterns - the Luxalp lanterns - that mount to the inside of an old barrel roof warehouse structure. The lanterns had to use very little power, be very light weight, and have uniform luminous intensity.

The client contacted our Company to design twelve (12) large multi-planar geometric shapes - each one unique - which attach accurately and precisely to a curved ceiling AND maintain the lowest plane parallel to the floor.

The Luxalp Lanterns - had to be fabricated with flame retardant materials and be UL-Rated.

What was the purpose of this project? What did the client request?

The La Kretz Innovation Campus (LKIC) is the new cleantech industry hub in Los Angeles. LKIC is a place where entrepreneurs, engineers, scientists and policymakers collaborate, promote and support the development of clean technologies and the green economy of Los Angeles.

The client requested that our Company design lanterns to be hung from the ceiling at the entry to the campus so that individuals would immediately be introduced to the architectural uniqueness of the clean technology campus. The client wanted 'art-type' lighting at the entry to the campus that bespoke the creative environment one was about to enter.

What is unique or complex about the project?

The client requested that our Company build models of each different shape - maintaining accurate relationships between all the important aspects. The geometry and size of each Luxalp lantern varied and several of the lanterns had to mirror concrete planters at ground level. Additionally, each lantern had to be attached to the ceiling so that the attachment method was not visible.

The lanterns are fabricated using 6061 aluminum tubing clad with an elastic polyurethane fabric that makes that the lantern shade very strong, supple and resistant to wear and tear over time.

The lighting components had to be integrated into each lantern in order to obtain the UL-rating, and because of the eco-friendly nature of the project, all of the lanterns had to be low-voltage and dimmable. LED lights were incorporated into the custom frames to provide consistent, low-heat, low voltage light.

What were the results of the project?

The Luxalp Lanterns are suspended from the ceiling and nested in between the wood trusses that support the roof. The top end of the lanterns matches the curvilinear barrel roof, while the bottom end of the lanterns is flat and is parallel to the floor. The lanterns range in size from 5-feet tall to just over 10-feet tall.

The lanterns were installed during the internal reconstruction of the building and were wrapped to keep clean and preserve the fixtures as construction was completed.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG