Company:

TenCate Geosynthetics Americas Pendergrass, GA

Project Details

Fabric 1

Mirafi

Producer:

TenCate Geosynthetics

Fabric 2

Miragrid

Producer:

TenCate Geosynthetics

Engineer Company 1

Gale-Tec Engineering

Design Company

HKS

Architect Company

HKS

Fabrication Company

TenCate Geosynthetics

Subcontractor Company

ASDCO, A Division of The Jamar Company

Project Manager Company

M.A. Mortenson Company, Inc.

Please describe the project specifications

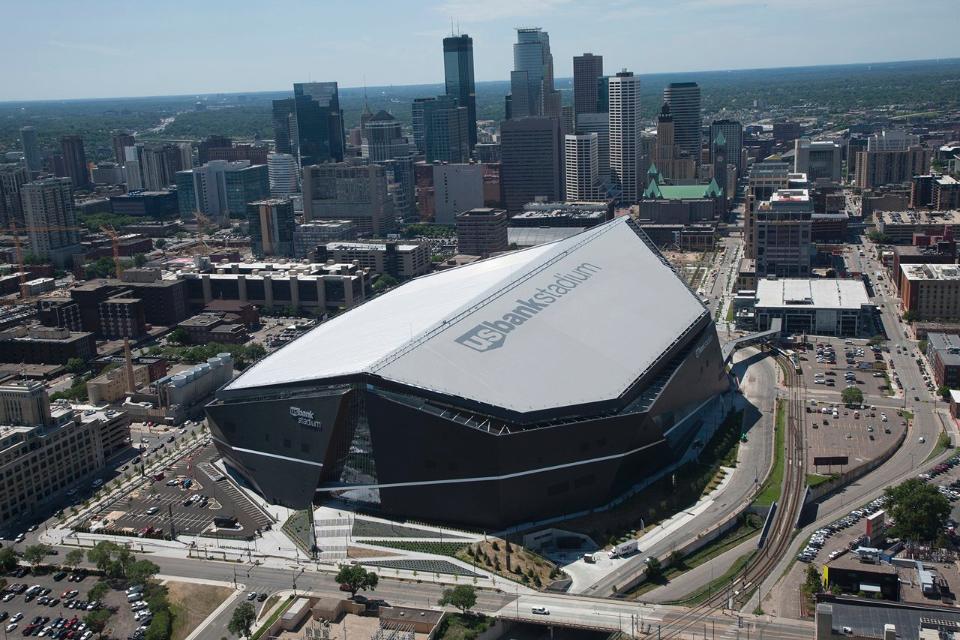

The project specific requirement was for the geosynthetic engineer to design a permanent wall system unique to the formidable site challenges at the U.S. Bank Stadium location in downtown Minneapolis, MN. On the southwest side of the stadium site, there were concerns that conventional, deep foundation solutions would have to be implemented which would be very expensive and drastically impact the project schedule. The proposed structure had to be a proven system that, while meeting the required structural purpose, provided economic, safety and ease of installation benefits. Stress Relief Wall, 25 feet high x 800 feet long = 20,000 square feet.

What was the purpose of this project? What did the client request?

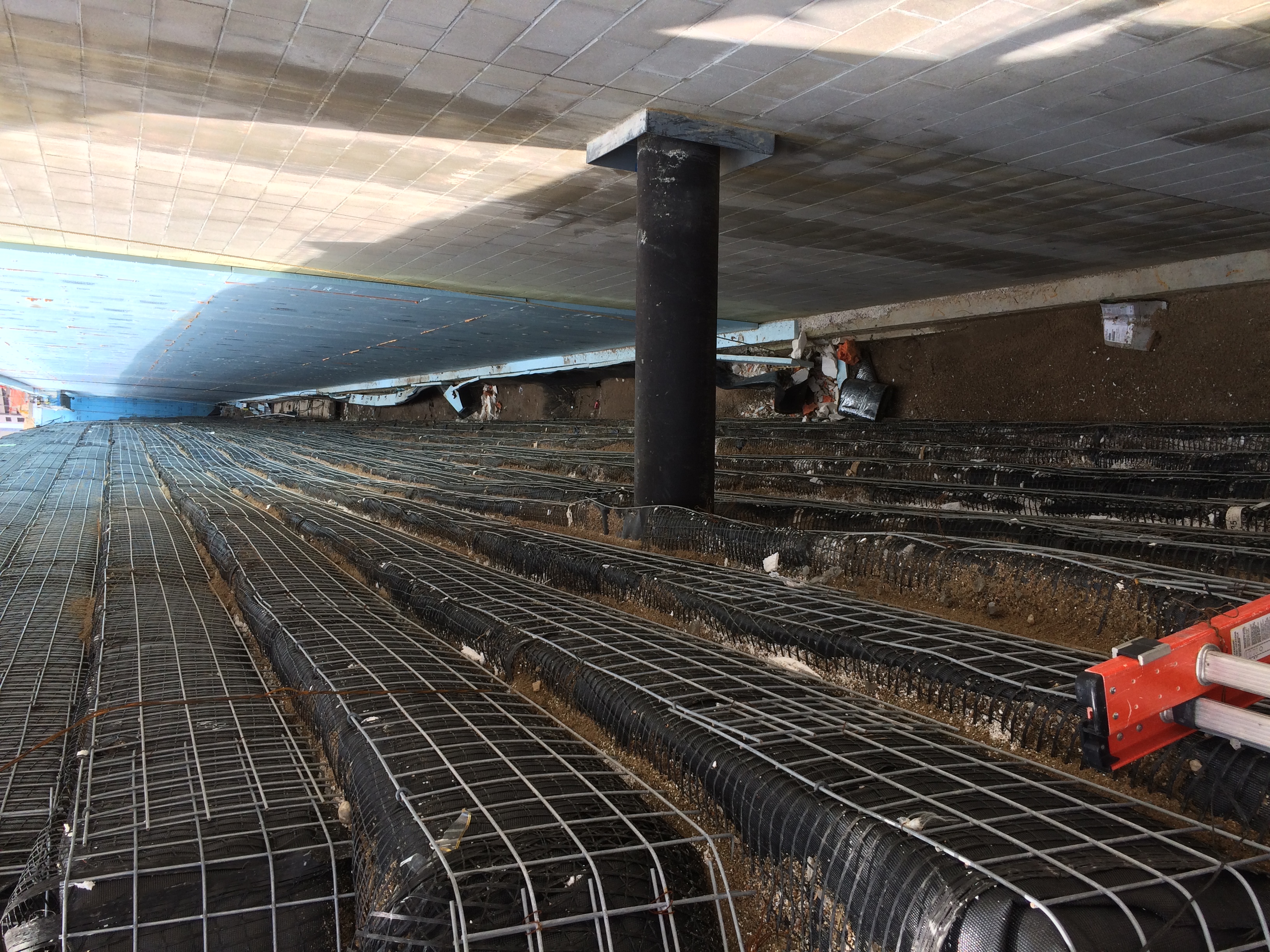

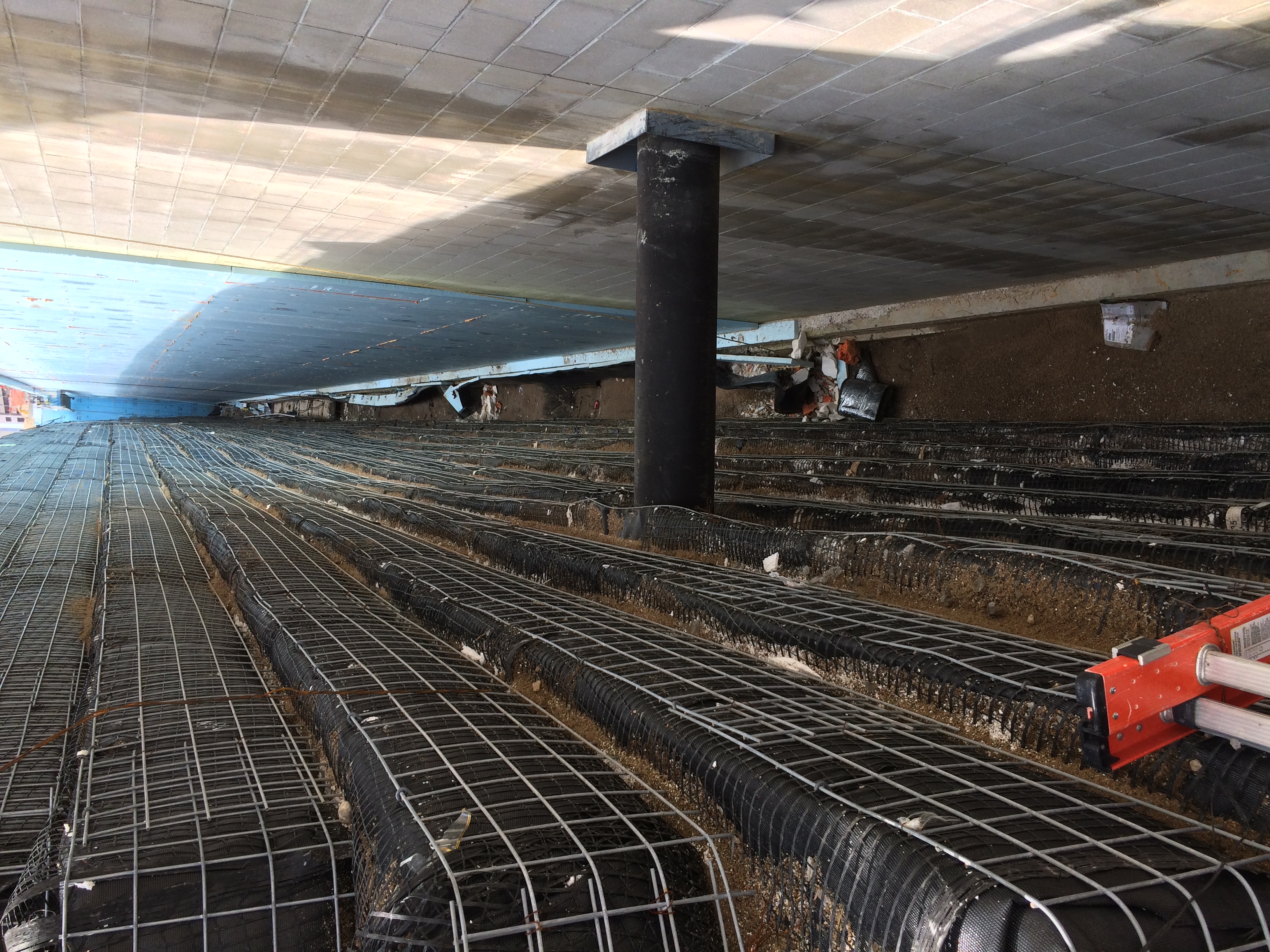

There are many instances where permanent stress relief walls are the most effective and economical solution when it is necessary to prevent imposed lateral loads on below grade structural walls. This was the case with the U.S. Bank Stadium where the Minnesota Vikings football team will play beginning the Fall of 2016. Consequently, the requirement was to design and build a permanent, below grade stress relief wall in close proximity to the structural wall on the southwest side of the new stadium. This was an alternative to cast in place concrete shear walls placed on footings to bedrock with rock anchors, which was utilized at other locations around the building. The accepted stress relief wall was required by the stadium designer to provide continual lateral soil load relief to the permanent outside wall of the building by creating a consistent, below grade void between the two structures.

What is unique or complex about the project?

Details had to be created to: tie the geogrid reinforcement into the pile caps supporting a pedestrian bridge with an anchor system, handle intersecting pipe inclusions, include a bypass system for a tower crane foundation that was introduced after the original wall design and to step the wall down beneath a concrete chevron. This specifically designed component wall system had the ability to easily vary slope height, inclination and geometric footprint. The mechanically stabilized earth (MSE) system consists of select soil reinforced with high strength geogrid, geosynthetic fabric and steel formwork to permanently function as a composite, monolithic mass. The MSE wall components and construction process using typical tools, equipment and labor, allowed for installation options which alleviated site constraints. Another feature of the wall system is that it allowed for the design engineer to use a near vertical angle in order to minimize the top of wall distance to the building.

What were the results of the project?

The client is extremely satisfied with the ease of installation and the ability to complete the stress relief wall in conjunction with stadium construction savings of over 5 million dollars as compared with alternative options. The below grade system is virtually maintenance free and the same system has been used by the contractors on many other projects.

Content is submitted by the participant. IFAI is not responsible for the content descriptions of the IAA award winners.

TEXTILES.ORG

TEXTILES.ORG